Precious metal surface treatment technology has a wide range of Applications in the fields of jewelry, electronics, medical devices and so on. Magnetic Polishing Machine, as a kind of efficient and environmentally friendly surface treatment method, has gradually been the attention of the industry. This paper will introduce the application of magnetic polishing machine in precious metal surface treatment and its advantages.

I. Introduction

Precious metals have good electrical conductivity, thermal conductivity and oxidation resistance, and are widely used in various fields. However, oxidization and abrasion on the surface of precious metals can affect their performance and aesthetics. Therefore, it is of great significance to treat the surface of precious metals. Magnetic polishing machine as a new surface treatment technology, with high efficiency, environmental protection, easy to operate and other advantages, and gradually become the preferred method of precious metal surface treatment .

Second, the working principle of magnetic polishing machine

Magnetic polishing machine using magnetic abrasive in the magnetic field, the role of the precious metal surface polishing. Its main components include: magnetic field generator, magnetic abrasive, polishing fluid and container. When working, put the precious metal into the container and add the magnetic abrasive and polishing liquid. The magnetic field generator produces a magnetic field so that the magnetic abrasive forms a high-speed moving Grinding layer on the surface of the precious metal. By adjusting the magnetic field strength, abrasive grain size and polishing time, the fine treatment of the precious metal surface is realized.

Third, the application of magnetic polishing machine in the surface treatment of precious metals

1. Jewelry industry: magnetic polishing machine can be used for gold, platinum and other precious metal jewelry polishing, improve the gloss and texture of jewelry. Compared with traditional polishing methods, magnetic polishing machine has higher polishing efficiency and better gloss.

2. electronic industry: magnetic polishing machine for precious metal wires, connectors and other electronic components of the surface treatment, improve its conductivity and oxidation resistance.

3. medical devices: magnetic polishing machine can be used for the polishing of precious metal parts in medical devices to improve the service life and biocompatibility of the devices.

4. High-end decoration: magnetic polishing machine can be used for clocks and watches, glasses and other high-end decorative surface treatment, improve product quality.

Fourth, the advantages of magnetic polishing machine in the surface treatment of precious metals

1. high efficiency: magnetic polishing machine polishing speed, greatly improving production efficiency.

2. environmental protection: magnetic polishing machine using water-based polishing fluid, no harmful gas emissions, in line with environmental requirements.

3. Fine: magnetic polishing machine can realize nano level surface treatment, improve the surface finish and uniformity of precious metals.

4. Easy to operate: magnetic polishing machine is easy to operate, no need for professional skills, reduce labor costs.

5. Wide range of application: magnetic polishing machine is suitable for surface treatment of precious metals of various shapes and sizes.

V. Conclusion

Magnetic polishing machine as an efficient, environmentally friendly precious metal surface treatment technology, has been widely used in many fields in China. With the continuous progress of technology, magnetic polishing machine will play a greater role in the precious metal surface treatment market, to provide strong support for the development of China's high-end manufacturing industry .

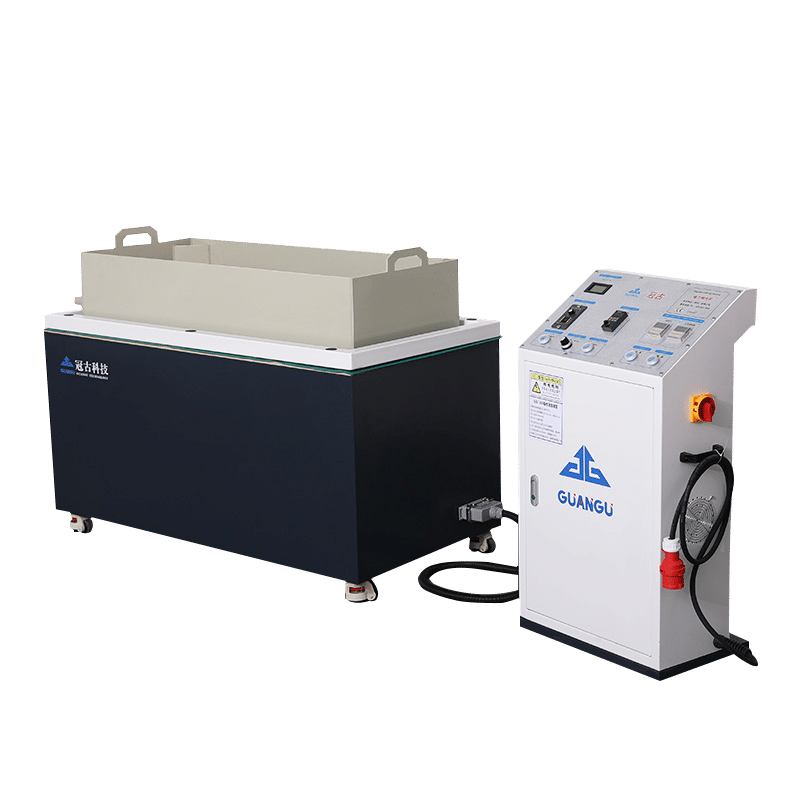

GG8520

GG8520 GG8620

GG8620 GG8720

GG8720 GG1380

GG1380 GG2380

GG2380 GG2980

GG2980 GG8850

GG8850 GG1980

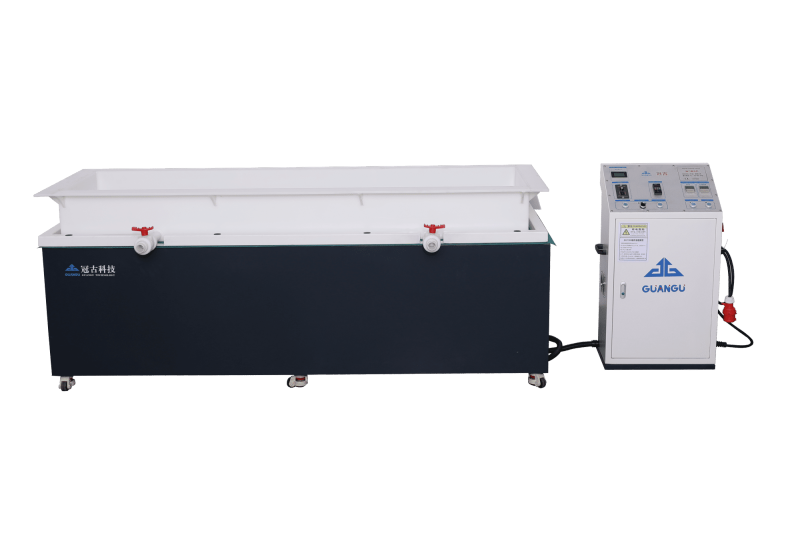

GG1980 flipping

flipping flameproof

flameproof sandblaster

sandblaster Flat polishing machine

Flat polishing machine