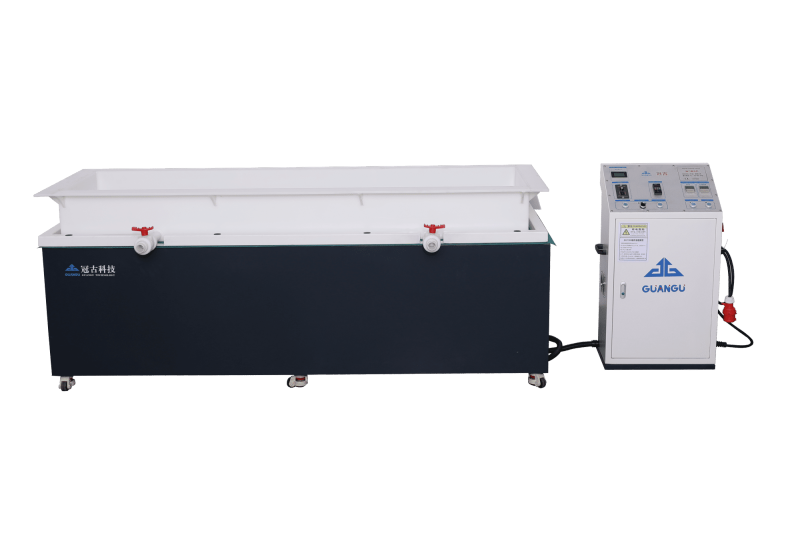

With the rapid development of science and technology, China's manufacturing industry is facing an important stage of transformation and upgrading. As an indispensable link in the manufacturing industry, Magnetic Grinding Machine plays an important role in improving product quality and enhancing production efficiency. In recent years, the development trend of magnetic Grinding machine intelligence is increasingly obvious, for the transformation and upgrading of China's manufacturing industry has injected a new impetus.

First, the magnetic grinding machine overview

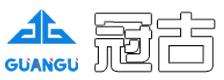

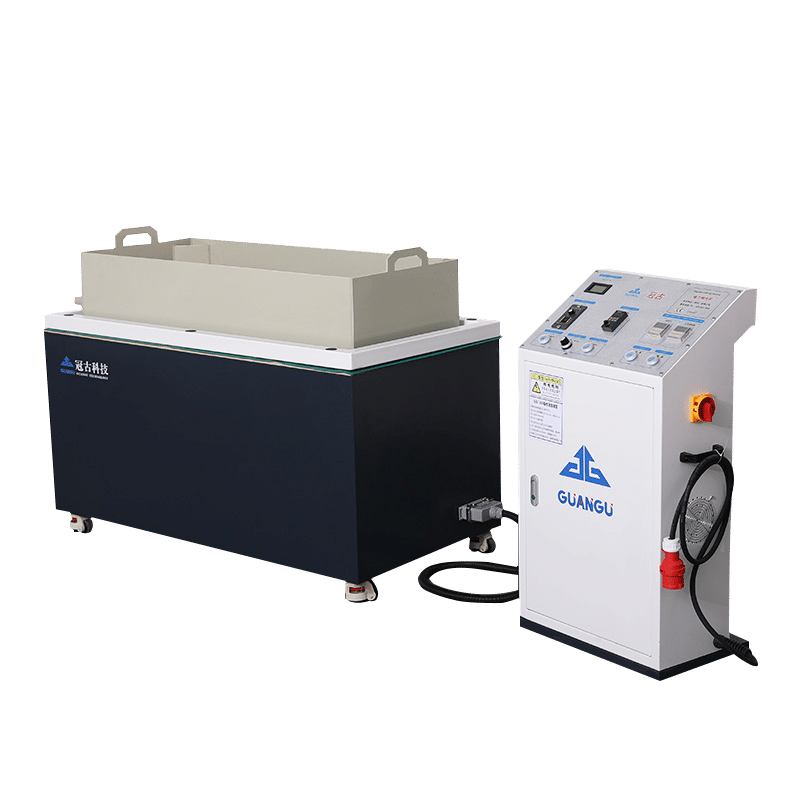

Magnetic lapping machine is a kind of high efficiency and precision processing equipment that utilizes magnetic abrasive to grind the workpiece under the action of magnetic field. It has the characteristics of fast grinding speed, high processing accuracy, wide range of Applications, widely used in aerospace, automotive, electronics, precision molds and other fields. Magnetic grinding machine is mainly composed of magnetic field generation system, grinding media, grinding tank, control system and other parts.

Second, the intelligent development trend of magnetic grinding machine

1. Grinding parameters adaptive adjustment

Traditional magnetic grinding machine in the processing, grinding parameters (such as magnetic field strength, grinding time, etc.) need to be manually adjusted, it is difficult to achieve optimal processing results. Intelligent magnetic grinder through the sensor real-time monitoring of the parameters of the grinding process, according to the workpiece material, shape and other factors, automatically adjust the grinding parameters, to achieve the optimization of the grinding effect.

2. Grinding path planning

Intelligent magnetic grinder can automatically plan the grinding path according to the shape and size of the workpiece to ensure uniform and efficient grinding. In addition, it can effectively avoid the problems of repeated grinding and insufficient grinding, and improve the processing quality.

3. Fault diagnosis and predictive maintenance

Intelligent magnetic grinding machine has the function of fault diagnosis and predictive maintenance. By monitoring the operating status of the equipment, analyzing the causes of failure, early warning of potential failures, reducing the equipment failure rate. At the same time, the predictive maintenance function helps to rationalize the maintenance schedule and reduce maintenance costs.

4. Networking remote control

With the help of Internet technology, intelligent magnetic grinding machine can realize remote monitoring, operation and data transmission. Enterprises can adjust and optimize the equipment remotely according to the production demand, and improve the production management efficiency.

Third, the impact of magnetic grinding machine intelligence on the manufacturing industry

1. Improve production efficiency

Intelligent magnetic grinding machine can automatically adjust the grinding parameters according to the characteristics of the workpiece, improve grinding efficiency, shorten the production cycle, reduce production costs.

2. Ensure the processing quality

Intelligent magnetic grinding machine has higher processing accuracy and consistency, which helps to improve product quality and enhance the competitiveness of enterprises.

3. Optimize production management

Through the network remote control, enterprises can grasp the real-time operating status of the equipment, real-time analysis and processing of production data, providing strong support for production management.

4. Reduce labor costs

Intelligent magnetic grinding machine reduces the dependence on operators, reduces labor costs, and helps enterprises achieve sustainable development.

In short, the intelligent development of magnetic grinding machine will bring unprecedented opportunities for China's manufacturing industry. Enterprises should seize this development trend, accelerate the application of intelligent equipment, promote the transformation and upgrading of the manufacturing industry, and contribute to the realization of high-quality development of the manufacturing industry.

GG8520

GG8520 GG8620

GG8620 GG8720

GG8720 GG1380

GG1380 GG2380

GG2380 GG2980

GG2980 GG8850

GG8850 GG1980

GG1980 flipping

flipping flameproof

flameproof sandblaster

sandblaster Flat polishing machine

Flat polishing machine