Shaped carbon steel parts usually produce burrs during the stamping or cutting process, which not only affect the aesthetic appearance of the product, but also may affect its function and safety. In order to effectively solve the burr problem of shaped carbon steel parts, Magnetic Grinding Machine is widely used. The following is a detailed description of the magnetic Grinding machine in solving the burr problem of shaped carbon steel parts:

The working principle of magnetic grinding machine

Magnetic lapping machine utilizes magnetic field to adsorb the grinding media (Stainless steel magnetic needle) on the surface of the workpiece, and removes the burr and roughness of the surface through rotary motion and friction. It can effectively clean and level all corners and curved parts of shaped carbon steel parts without damaging the surface of the workpiece.

Methods of solving burrs on shaped carbon steel parts

Precise grinding: The magnetic grinding machine can precisely control the movement path and strength of the grinding media, so as to carry out fine grinding for the different shapes and structures of the shaped carbon steel parts, and effectively eliminate burrs.

Multi-angle processing: The equipment is able to adjust the magnetic field and the position of the grinding media to achieve the ability of multi-angle processing of shaped workpieces, ensuring that each part can be fully cleaned and polished.

Roughness Removal: Through continuous rotation and abrasive action, the magnetic lapping machine is able to quickly and effectively remove the roughness from the surface of carbon steel parts to achieve the smoothness and surface quality required by the design.

Automated operation: The equipment is usually highly automated, capable of automatic processing after setting the parameters, reducing the need for manual operation while improving the consistency and efficiency of processing.

Enhanced product quality: Magnetic lapping machines ensure the surface finish and consistency of shaped carbon steel parts, thus enhancing the product's aesthetic appearance and functionality.

Cost Savings: Compared to manual deburring or other machining methods, magnetic lapping machines can significantly reduce labor costs and cycle times, increasing productivity.

Environmental protection and safety: As it does not produce dust and chemical waste liquid, magnetic grinding machine meets the requirements of environmental protection, and at the same time improves the work safety of the operators.

In summary, magnetic grinding machine as the ideal choice to solve the problem of burrs on shaped carbon steel parts, not only can effectively improve the processing efficiency and product quality, but also to meet the needs of modern manufacturing industry for high precision, environmental protection and safety.

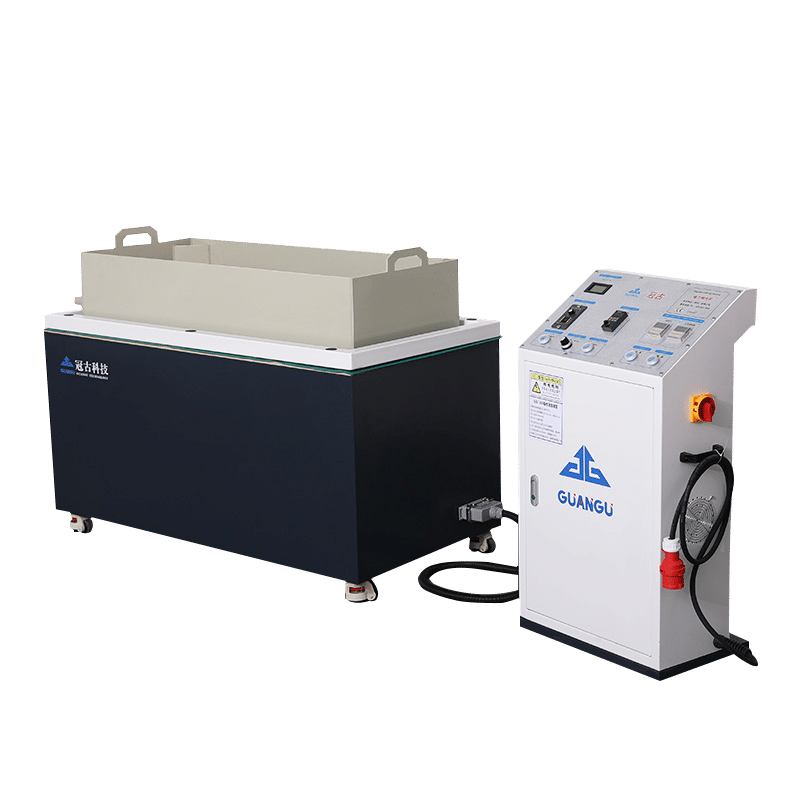

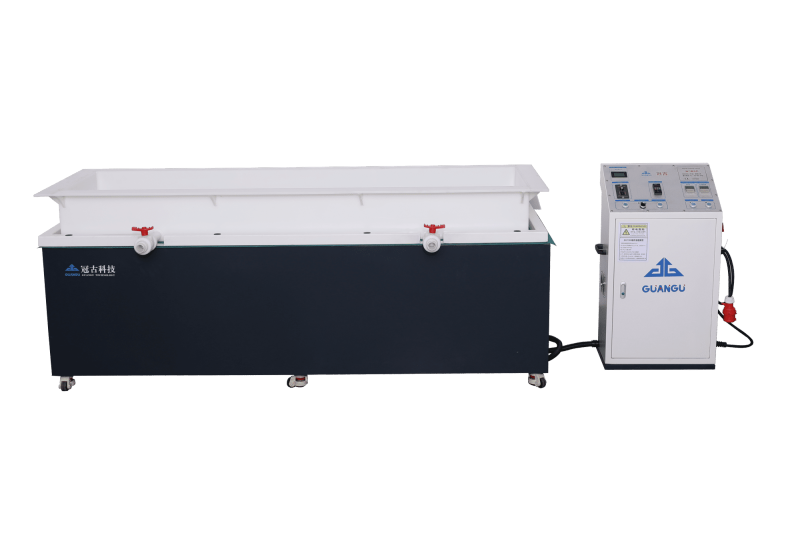

GG8520

GG8520 GG8620

GG8620 GG8720

GG8720 GG1380

GG1380 GG2380

GG2380 GG2980

GG2980 GG8850

GG8850 GG1980

GG1980 flipping

flipping flameproof

flameproof sandblaster

sandblaster Flat polishing machine

Flat polishing machine