In the hall of modern manufacturing industry, Magnetic Polishing Machine is like a magician who controls the fate of metal, giving metal parts a new life with its unique magic. When those rough and dull metal parts are fed into this magical equipment, a shocking transformation begins.

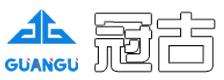

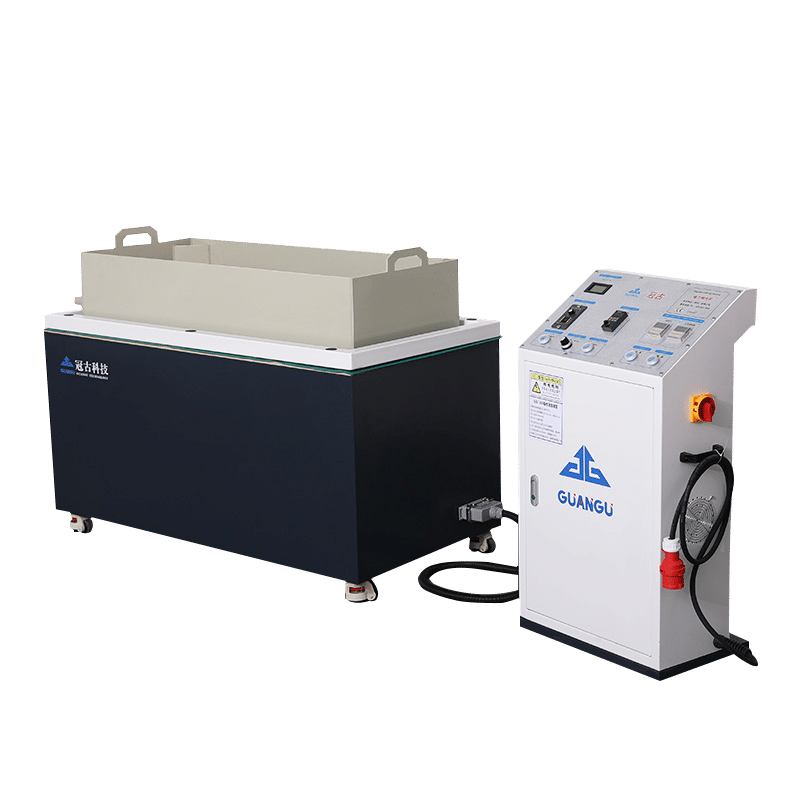

The working principle of magnetic polishing machine can be called a miracle of modern industry. It uses a strong magnetic field to drive Stainless steel needles to move at high speed on the surface of parts. These tiny needles are like thousands of troops, under the command of electromagnetic force, they impact and grind the surface of parts accurately and orderly. Each needle carries huge energy, but maintains perfect order under precise control. This perfect combination of power and control is amazing.

When the machine starts, the whole workshop seems to be shaking. Metal parts roll in the polishing tank, and stainless steel needles form turbulent eddies under the action of the magnetic field. In the harsh sound of metal friction, the oxide layer, burrs and defects on the surface of parts are ruthlessly stripped off. This kind of stripping is not a simple removal, but a precise carving, which is a rearrangement of the molecular structure of the metal surface. Every metal atom is experiencing the pain of rebirth and is reborn in the pain.

Every detail in the polishing process is shocking. Every collision between the stainless steel needle and the surface of the part will produce tiny sparks, which are interwoven into a dazzling light network in the tank. The roughness of the metal surface is reduced at a speed visible to the naked eye, and the glossiness is constantly improving. The originally gray surface gradually shows a mirror-like luster. This transformation is so rapid and thorough that it seems that time is accelerating on the metal surface.

When the polishing is completed and the part is taken out of the tank, the shock reaches its peak. The originally ordinary metal parts now glow with dazzling brilliance, with a smooth surface like a mirror and rounded and smooth edges. Every detail has reached micron-level precision, and every contour shows perfect geometric beauty. This transformation is not only a change in the surface, but also a sublimation of the essence of metal.

The magnetic polishing machine brings not only the smoothness of the surface, but also the quenching of the metal soul. In this process, we witnessed the power of science and technology and felt the beauty of industry. This machine not only changes the appearance of metal, but also changes our perception of manufacturing. It tells us that even in the hardest metal, there are infinite possibilities. As long as the right power and conditions are given, shocking beauty can be inspired.

This is the magic of the Magnetic Polisher, and this is the miracle of modern manufacturing. In this era full of machinery and technology, we can still witness such a shocking transformation. This is not only a victory of technology, but also a testimony of human wisdom. Every polishing is a rebirth; every part is a work of art. This is the shock that the magnetic polisher brings us, and this is the best interpretation of the beauty of industry.

GG8520

GG8520 GG8620

GG8620 GG8720

GG8720 GG1380

GG1380 GG2380

GG2380 GG2980

GG2980 GG8850

GG8850 GG1980

GG1980 flipping

flipping flameproof

flameproof sandblaster

sandblaster Flat polishing machine

Flat polishing machine