Introduction: In the fierce market competition, Copper inlay manufacturers are seeking transformation and upgrading to improve product quality and reduce production costs. The introduction of Magnetic Polishing Machines has become a powerful measure for many manufacturers to enhance their competitiveness. This article will explore the Application of magnetic polishing machines in the production of copper inlays and the benefits they bring.

1. Background introduction

Copper inlays are widely used in electronics, electrical appliances, communications, hardware and other industries. The market demand is growing year by year. However, with the intensification of market competition, consumers have higher and higher requirements for the quality of copper inlays. In order to meet market demand, copper inlay manufacturers are seeking transformation and upgrading to improve product quality.

2. Application of magnetic polishing machines in copper inlay production

Principle of magnetic polishing machine

Magnetic polishing machines use magnetic fields to guide magnetic abrasives, so that abrasives flow and impact the workpiece at high speed, thereby removing burrs, scales, and improving the surface finish of the workpiece.

Advantages of magnetic polishing machine in copper inlay production

(1) Improve production efficiency: Magnetic polishing machine can realize mass production, greatly shorten the production cycle and improve production efficiency.

(2) Improve product quality: The surface finish of copper inlay polished by magnetic polishing machine is higher, and the problems of burrs and oxide scale are effectively solved, which improves product quality.

(3) Reduce production cost: Magnetic polishing machine is easy to operate and saves labor cost; abrasive consumption is low, which reduces raw material cost.

(4) Environmental protection and energy saving: Magnetic polishing machine uses water-based abrasive, which is pollution-free and complies with national environmental protection policies.

3. Magnetic polishing machine helps copper inlay manufacturers transform and upgrade

Improve product competitiveness

After the introduction of magnetic polishing machine, the product quality of copper inlay manufacturers has been significantly improved, meeting the demand of high-end market for high-quality copper inlays and improving product competitiveness.

Expand market scope

Relying on the high quality advantage of magnetic polishing machine, copper inlay manufacturers can gradually expand market scope, enter the high-end market and achieve sustainable development of enterprises.

Optimize production process

The application of magnetic polishing machine makes the production process of copper inlay manufacturers more refined and intelligent, reduces waste in the production process, and improves production efficiency.

IV. Conclusion

In short, the introduction of magnetic polishing machine by copper inlay manufacturers is an inevitable choice to meet market demand, improve product quality and reduce production costs. With the continuous maturity of magnetic polishing technology, it is believed that more and more copper inlay manufacturers will benefit from this advanced equipment, realize the transformation and upgrading of enterprises, and contribute to the development of my country's copper inlay industry.

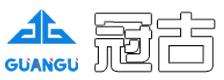

GG8520

GG8520 GG8620

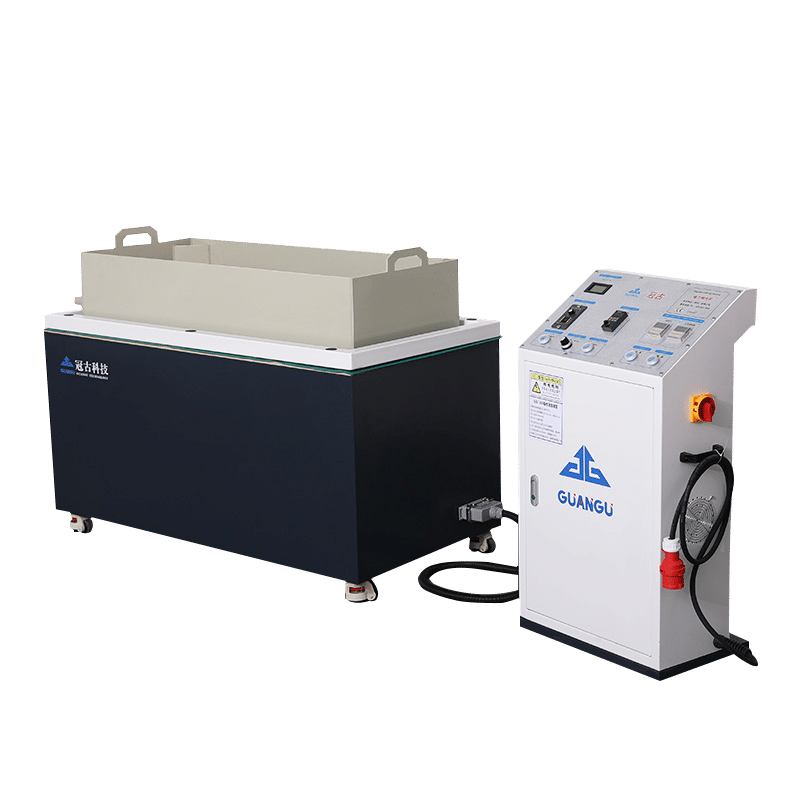

GG8620 GG8720

GG8720 GG1380

GG1380 GG2380

GG2380 GG2980

GG2980 GG8850

GG8850 GG1980

GG1980 flipping

flipping flameproof

flameproof sandblaster

sandblaster Flat polishing machine

Flat polishing machine