The core technology of the Magnetic Levitation Grinder lies in the use of magnetic force to control the Grinding tool. By precisely adjusting the electromagnetic field, the grinding tool is able to levitate and rotate at high speed without contact. This non-contact operation not only eliminates the mechanical friction of traditional grinding, but also realizes precise control of the grinding process.

The advantages of magnetic levitation grinding technology are mainly reflected in the following aspects:

Ultra-high precision: Micron and even nano-scale machining accuracy can be achieved.

Low heat generation: No mechanical contact means less heat generation, reducing the effects of thermal deformation.

Quiet operation: The magnetic levitation principle greatly reduces noise and improves the working environment.

Long service life: no mechanical wear and tear significantly extends the service life of equipment and tools.

High flexibility: grinding parameters can be easily adjusted to suit different processing needs.

In industrial Applications, the magnetic levitation mill shows great potential. In the semiconductor industry, it is used for precision flattening of wafers; in the optical industry, it can process high-precision lenses and prisms; in precision machinery manufacturing, it is used to process various high-precision parts. In addition, magnetic levitation mills also play an important role in cutting-edge fields such as new materials research and development and aerospace.

With the advancement of Industry 4.0 and intelligent manufacturing, magnetic levitation grinding machine is deeply integrating with artificial intelligence, big data and other technologies. Intelligent magnetic levitation grinding system can automatically adjust the parameters according to the material characteristics and processing requirements, further improving the processing efficiency and quality stability.

Looking to the future, there is still a lot of room for development of magnetic levitation grinding technology. With the advancement of material science and control technology, we are expected to see higher precision and higher efficiency of the magnetic levitation grinding equipment. This technology will not only continue to promote the precision and intelligence of the manufacturing industry, but may also give rise to completely new processes and products, injecting new vitality into industrial development.

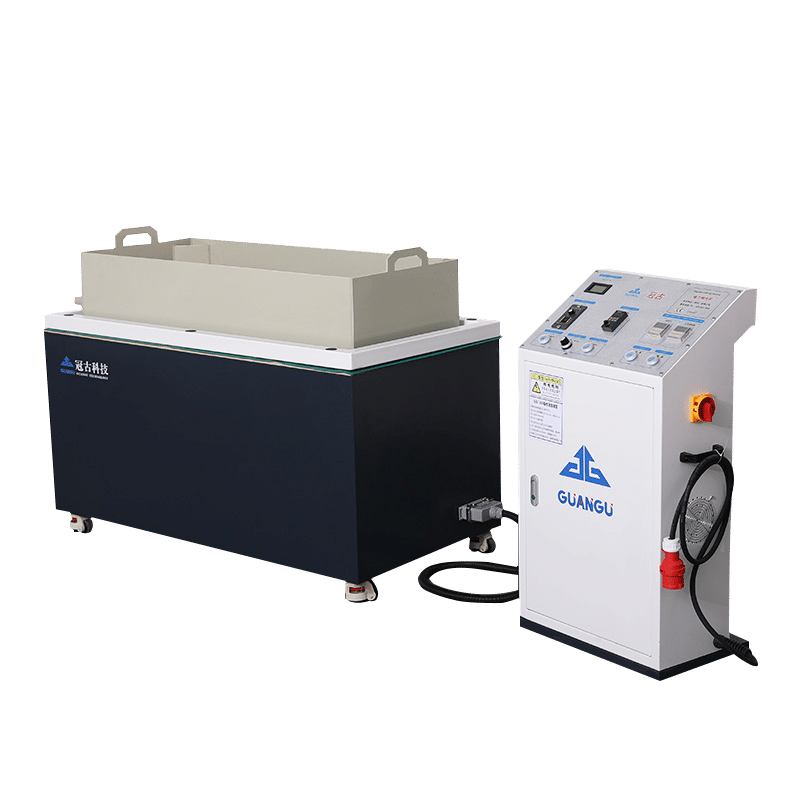

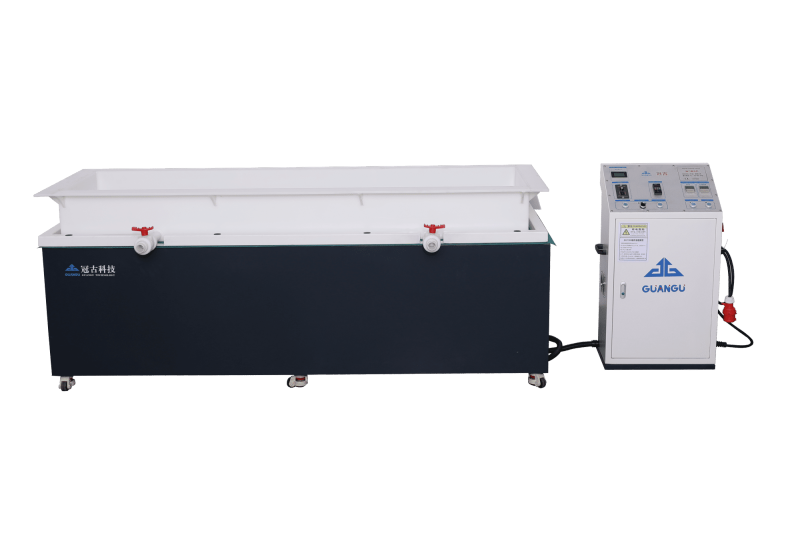

GG8520

GG8520 GG8620

GG8620 GG8720

GG8720 GG1380

GG1380 GG2380

GG2380 GG2980

GG2980 GG8850

GG8850 GG1980

GG1980 flipping

flipping flameproof

flameproof sandblaster

sandblaster Flat polishing machine

Flat polishing machine