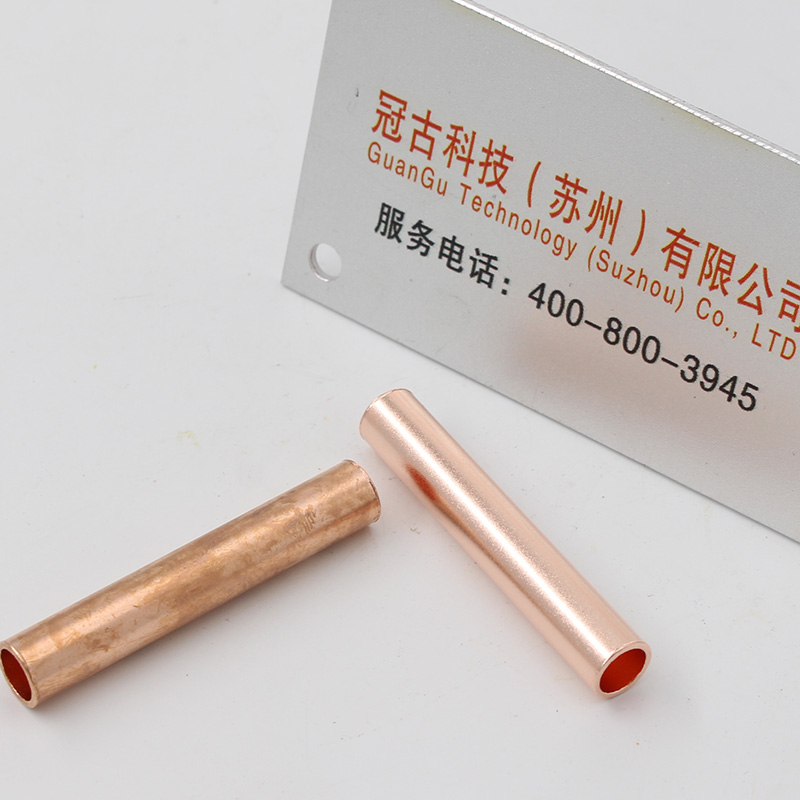

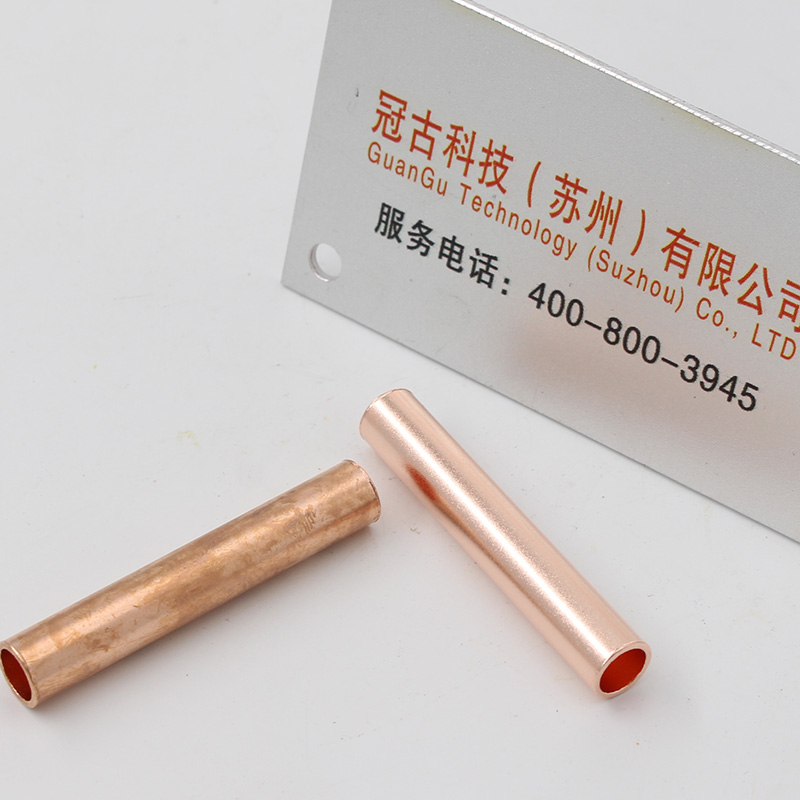

Magnetic Polishing Machine: a revolutionary solution for the surface treatment of bent pipes

In the field of precision manufacturing, the surface treatment of bent pipes has long faced technical bottlenecks that are difficult to break through with traditional processes. As an innovative surface treatment equipment, the magnetic polishing machine is completely changing the quality standards of bent pipe manufacturing. Its unique processing advantages show amazing results in the manufacturing of precision pipes such as automotive oil pipes and medical device catheters.

1. Congenital defects of traditional processes

Manual polishing has obvious process limitations. When operators use sandpaper or Grinding heads to process bent pipes, the blind spots on the inner wall and complex curved surfaces become insurmountable technical obstacles. Statistics show that the incomplete grinding rate of the inner wall of bent pipes with a diameter of less than 20mm is as high as 65%, and the residual burrs directly lead to a 40% increase in the failure rate of the hydraulic system. Although chemical polishing can handle complex structures, the microscopic corrosion caused by strong acid solutions reduces the uniformity of the pipe wall thickness by 0.02-0.05mm, which poses a serious safety hazard to medical equipment such as precision infusion tubes.

2. Physical innovation of magnetic polishing

The magnetic polishing machine accurately controls the movement trajectory of Stainless steel needle abrasives through electromagnetic fields to form a three-dimensional grinding matrix. When the frequency is set at 25-40Hz, the abrasive group can produce a vortex effect at the 90° bend, achieving uniform grinding of the R corner. This non-contact processing keeps the surface roughness stable within Ra0.2μm, and can maintain the amazing accuracy of the pipe wall thickness tolerance of ±0.01mm. After a certain aviation hydraulic pipeline manufacturer adopted this technology, the fatigue life of the product increased by more than 3 times.

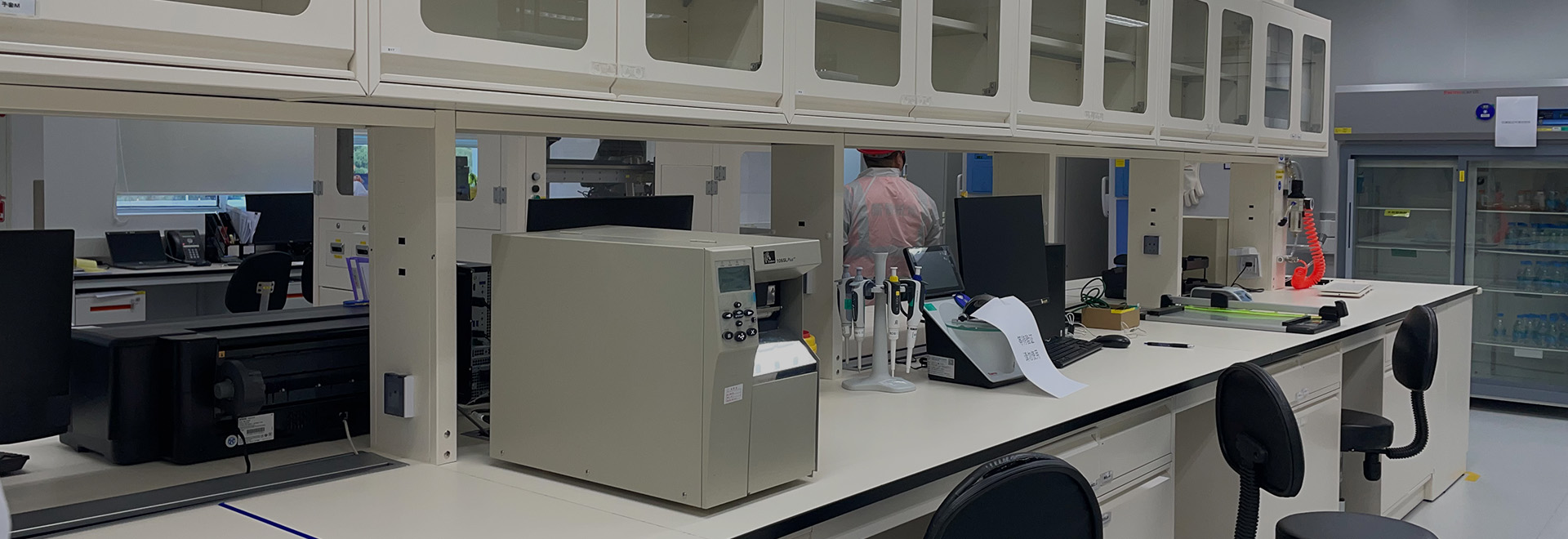

3. Key breakthroughs in intelligent manufacturing

On the automated production line, the magnetic polishing machine shows excellent adaptability. Through the PLC control system, the magnetic field strength (500-2000 Gauss) and processing time (3-15 minutes) can be automatically matched to different materials such as 316L stainless steel and titanium alloy. Industrial test data show that the processing efficiency is 80% higher than that of traditional processes, energy consumption is reduced by 45%, and zero wastewater discharge is achieved. After a new energy vehicle company introduced this equipment, the brake line production capacity jumped from 2,000 pieces per day to 10,000 pieces, and the quality complaint rate dropped to 0.03%.

This breakthrough in surface treatment technology marks a fundamental shift in pipe bending manufacturing from experience-oriented to scientific quantification. With the continuous optimization of intelligent control systems, magnetic polishing is reshaping the quality dimension of precision pipe manufacturing and providing key technical support for high-end equipment manufacturing. This innovation in physical processing not only solves the process problems caused by geometric complexity, but also opens a new era of micro-surface engineering.

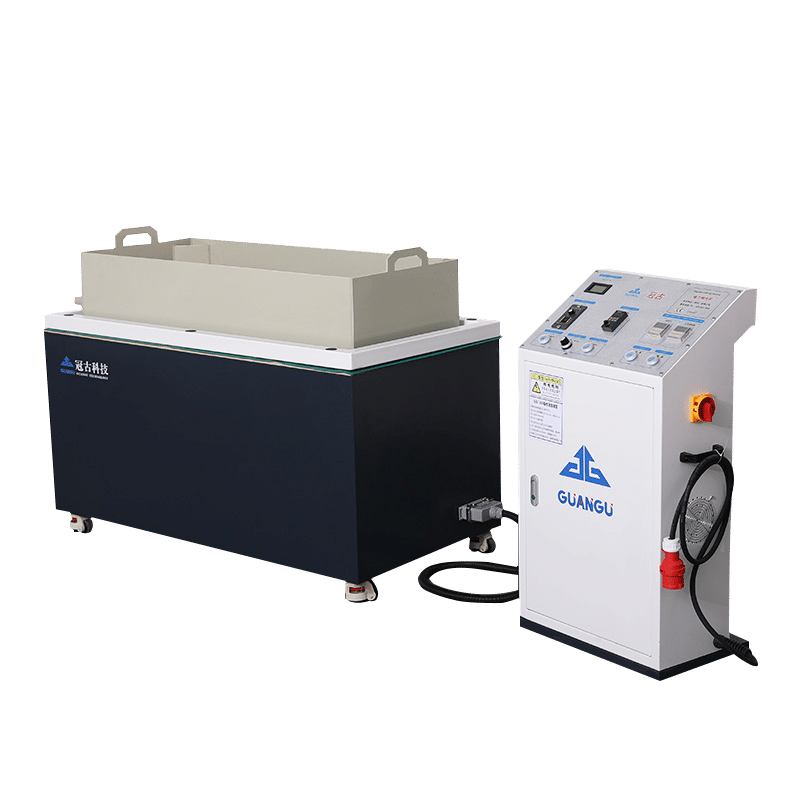

GG8520

GG8520 GG8620

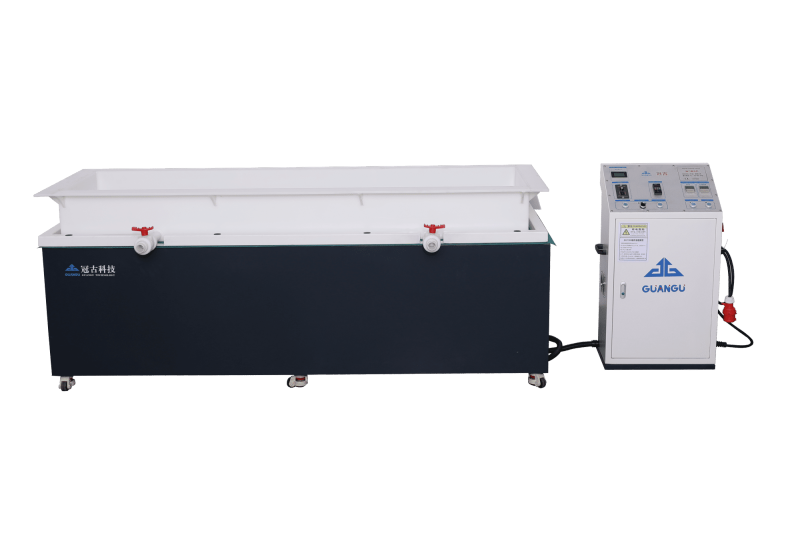

GG8620 GG8720

GG8720 GG1380

GG1380 GG2380

GG2380 GG2980

GG2980 GG8850

GG8850 GG1980

GG1980 flipping

flipping flameproof

flameproof sandblaster

sandblaster Flat polishing machine

Flat polishing machine