This article mainly introduces a new type of equipment in the Copper nose polishing process-Magnetic Polishing Machine. By analyzing the principle, advantages and Application range of the magnetic polishing machine, it provides an efficient and environmentally friendly polishing solution for copper nose processing enterprises.

I. Introduction

Copper nose is a commonly used connector in the electronics and electrical industries. Its main functions are conductivity, fixation and connection. The quality of copper nose products directly affects the stability and safety of the entire circuit system. In the production process of copper noses, polishing is a crucial process, which not only affects the appearance quality of the product, but also affects the service life of the product. Traditional polishing methods have certain limitations, such as low efficiency and serious pollution. With the development of science and technology, a new type of polishing equipment-magnetic polishing machine came into being, providing a new choice for copper nose polishing.

II. Principle and advantages of magnetic polishing machine

Principle

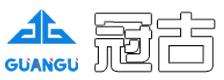

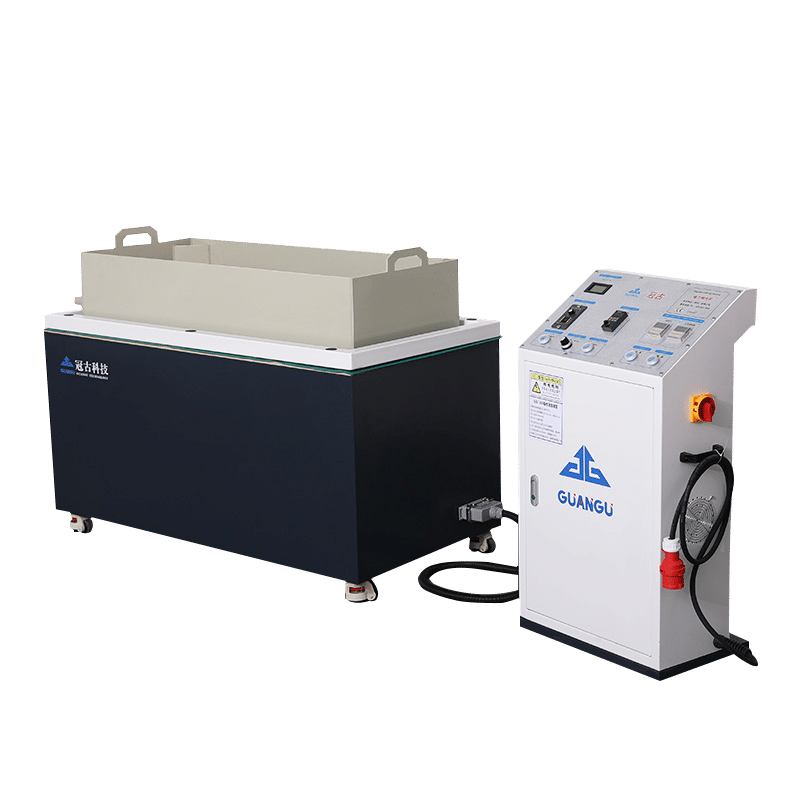

The magnetic polishing machine uses the magnetic field to generate magnetic force on the magnetic abrasive, so that the abrasive rubs the surface of the workpiece at high speed, thereby achieving the purpose of polishing. The magnetic polishing machine is mainly composed of a magnetic field generator, abrasive, polishing liquid and a control system. When working, the magnetic field generator generates a strong magnetic field, which makes the abrasive adsorb on the surface of the workpiece. As the magnetic field changes, the abrasive rubs the workpiece at high speed to remove the surface oxide layer, burrs, etc., and achieve polishing.

Advantages

(1) High efficiency: The magnetic polishing machine has a fast polishing speed and high efficiency, which is several times or even dozens of times that of traditional polishing methods.

(2) Environmental protection: The magnetic polishing machine uses water-based polishing liquid, which is pollution-free and meets national environmental protection requirements.

(3) Consistency: During the polishing process of the magnetic polishing machine, the magnetic field acts evenly on the abrasive, ensuring the consistency of the workpiece polishing.

(4) Manpower saving: The magnetic polishing machine has a high degree of automation, is easy to operate, and saves labor costs.

(5) Wide range of applications: The magnetic polishing machine is suitable for polishing copper noses of various shapes and sizes, and has high versatility.

III. Application of magnetic polishing machine in copper nose polishing

Polishing effect

The surface finish of the copper nose can reach below Ra0.2 when the magnetic polishing machine is used to polish the copper nose, and the appearance is beautiful without defects such as oxide layer and burrs.

Polishing efficiency

The polishing speed of the magnetic polishing machine is much higher than that of the traditional polishing method, which greatly shortens the production cycle and improves the efficiency of the enterprise.

Polishing cost

Although the initial investment of the magnetic polishing machine is high, in the long run, its operating cost is low, mainly reflected in labor costs, abrasive consumption and other aspects.

IV. Conclusion

As a new type of polishing equipment, the magnetic polishing machine has significant advantages in the field of copper nose polishing. It not only improves the polishing efficiency and reduces the production cost, but also meets the national environmental protection requirements. With the continuous maturity of magnetic polishing technology, it is believed that its application in the copper nose processing industry will become more and more extensive.

GG8520

GG8520 GG8620

GG8620 GG8720

GG8720 GG1380

GG1380 GG2380

GG2380 GG2980

GG2980 GG8850

GG8850 GG1980

GG1980 flipping

flipping flameproof

flameproof sandblaster

sandblaster Flat polishing machine

Flat polishing machine