In modern manufacturing, surface treatment technology is critical to product quality and performance. This article will focus on comparing two advanced metal surface treatment methods: magnetic needle polishing technology (especially rotary magnetic needle polishing machine) and traditional electrolytic polishing process, and introduce their advantages in the field of aluminum polishing Applications.

Overview of magnetic needle polishing technology

Working principle

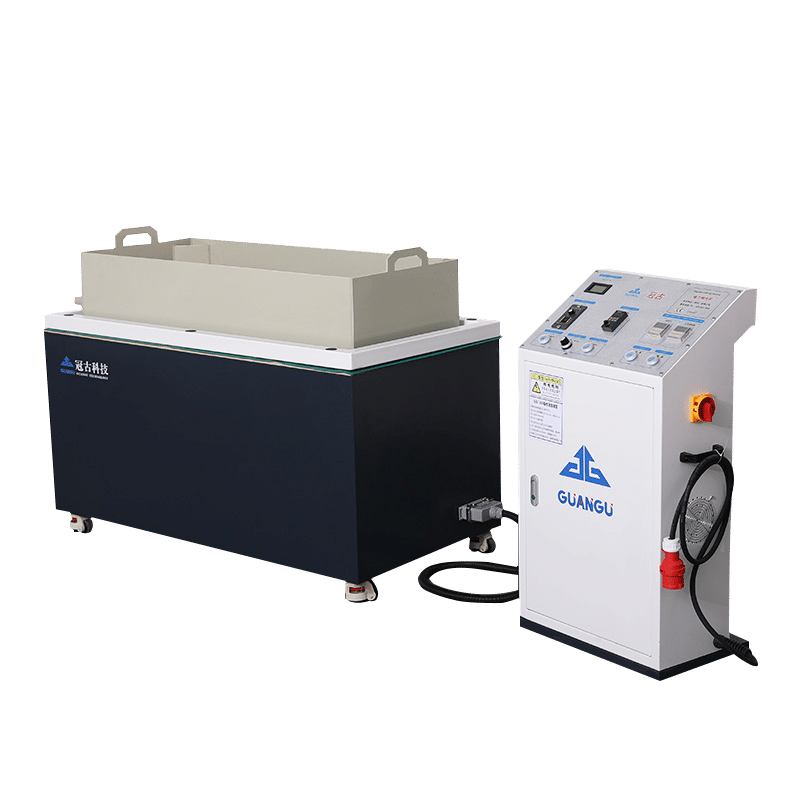

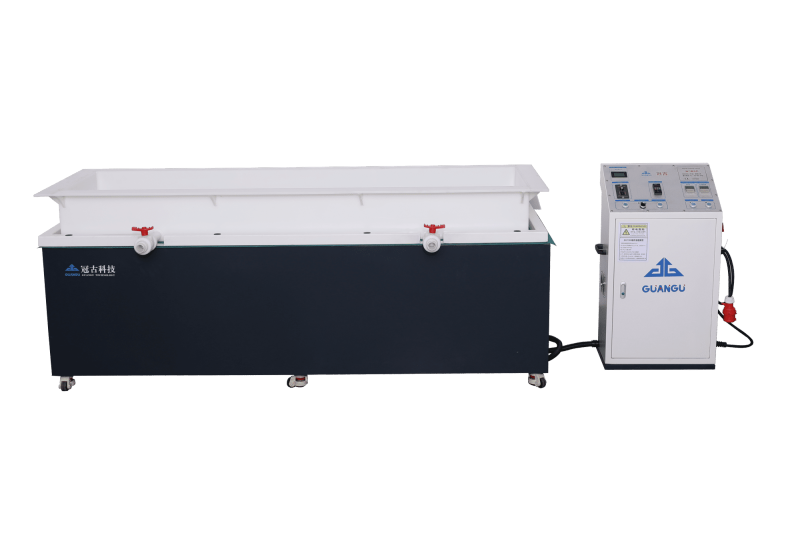

Magnetic needle polishing machine using a magnetic field, so that the magnetic polishing needle in the surface of the workpiece high-speed movement, to achieve surface polishing. Rotary magnetic needle polishing machine through the rotation of the magnetic field, so that the magnetic needle to produce complex trajectory, so as to achieve more efficient and uniform polishing effect.

Advantages

Highly efficient: able to process large quantities of workpieces quickly.

Environmental protection: no need to use chemical reagents to reduce environmental pollution.

Strong applicability: can handle complex shapes of workpieces.

Good surface quality: high gloss and low roughness can be realized.

Electrolytic Polishing Process Overview

Principle of operation

Electrolytic polishing involves immersing the workpiece as an anode in an electrolytic solution, which dissolves the surface of the workpiece through electrochemical reaction to realize the polishing effect.

Advantages

High surface finish: Mirror effect can be achieved.

Stress relief: improves the stress condition on the surface of the workpiece.

Good uniformity: for simple shaped workpieces, the polishing effect is uniform.

Comparison of aluminum polishing

Advantages of magnetic needle polishing machine in aluminum polishing

High efficiency: Compared with electrolytic polishing, magnetic needle polishing is faster.

No risk of corrosion: avoiding the potential corrosion of aluminum by electrolyte.

Applicable to complex shapes: for shaped aluminum parts, the magnetic needle polishing effect is better.

Energy saving and environmental protection: no need for large amounts of chemical reagents and electricity.

Limitations of electrolytic polishing in aluminum processing

Slow processing speed: especially for large aluminum parts

High consumption of chemicals: Increase cost and environmental burden

Poor results on complex shapes of aluminum parts: prone to uneven polishing.

Conclusion

The rotary magnetic needle polishing machine shows obvious advantages in the field of aluminum polishing, especially suitable for the processing of large quantities and complex shapes of aluminum products. It offers a more efficient, environmentally friendly and adaptable solution than the traditional electrolytic polishing process. However, electrolytic polishing still has its unique advantages in some specific applications, such as ultra-high finish requirements.

Manufacturers should choose the appropriate polishing technology for their specific needs. For most aluminum processing needs, rotary magnetic pin polishing machines are certainly an innovative option to consider.

GG8520

GG8520 GG8620

GG8620 GG8720

GG8720 GG1380

GG1380 GG2380

GG2380 GG2980

GG2980 GG8850

GG8850 GG1980

GG1980 flipping

flipping flameproof

flameproof sandblaster

sandblaster Flat polishing machine

Flat polishing machine