The manufacture of medical devices has very high requirements on the surface quality of parts, and magnetic lapping machine as a kind of efficient polishing tool, plays an important role in the manufacture of medical devices. This article will introduce the requirements of medical device parts polishing process, and the Application of Magnetic Grinding Machine in this process and technical points.

1. Key requirements of medical device parts polishing

The surface of medical device parts must be smooth, burr-free, pollution-free, and in line with strict health standards and biocompatibility requirements. Therefore, the polishing process not only requires high efficiency, but also needs to ensure that the shape and dimensional accuracy of the parts are not affected.

2. Advantages and applicability of magnetic Grinding machines

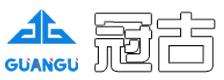

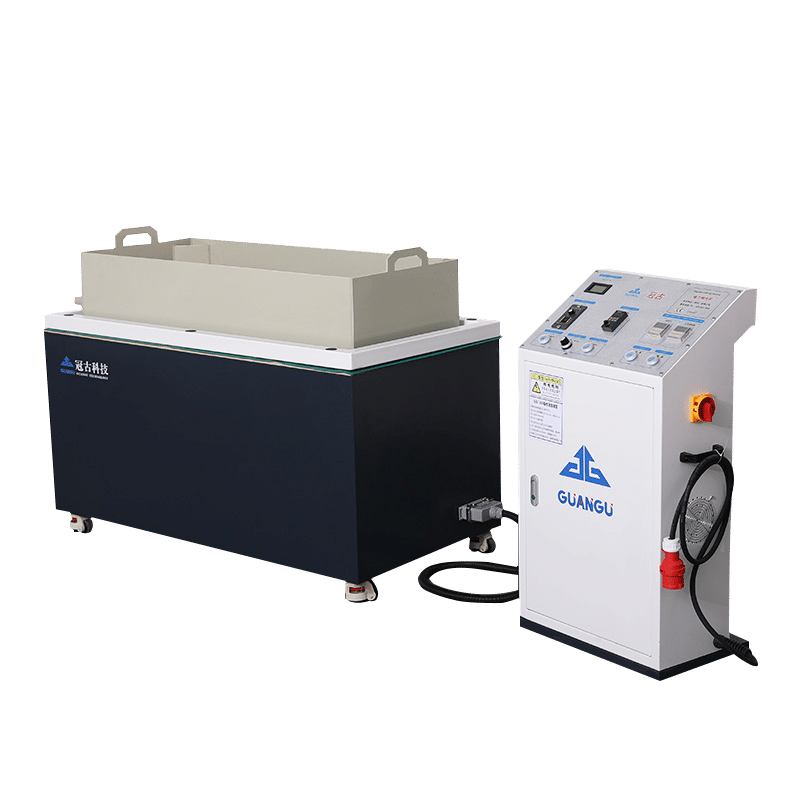

Highly efficient polishing capability: Magnetic lapping machines attach abrasives (Stainless steel needles) to the surface of the part by means of a magnetic field, enabling burrs and surface irregularities to be removed quickly and uniformly.

Protection of Part Surface and Shape: Due to its non-contact operation, the Magnetic Mill maintains the accuracy and shape integrity of the part.

Compliance with hygiene standards: The materials and design of the equipment meet the hygiene requirements of the medical device industry and are suitable for use in demanding production environments.

3. Technical Practices and Operational Guidelines

Polishing parameter settings: including polishing time, abrasive (stainless steel needle) selection, magnetic field strength and other parameters of the settings, according to the specific part materials and polishing requirements for adjustment.

GG8520

GG8520 GG8620

GG8620 GG8720

GG8720 GG1380

GG1380 GG2380

GG2380 GG2980

GG2980 GG8850

GG8850 GG1980

GG1980 flipping

flipping flameproof

flameproof sandblaster

sandblaster Flat polishing machine

Flat polishing machine