- Language

-

China(简体中文) Taiwan, China(繁体中文) Thailand(Thai) Vietnam(Vietnamese) Singapore(English) India(English) Japan(Japanese) Australia(English) Bangladesh(English) Indonesia(English) Korea(English) Malaysia(English) Pakistan(English) Philippines(English) Afghanistan(English)Austria(Deutsch) Belgium(French) Bulgaria(English) Croatia(English) Czech Republic(English) Denmark(English) Estonia(English) Finland(English) France(French) Germany(Deutsch) Greece(English) Azerbaijan(Russian) Hungary(English) Ireland(English) Italy(English) Kazakhstan(Russian) Latvia(Russian) Luxembourg(Deutsch) Netherlands(English) Norway(English) Poland(English) Portugal(English) Romania(English) Slovakia(English) United Kingdom(English) Ukraine(Russian) Switzerland(Deutsch) Sweden(English) Serbia(English) Spain(English) Russia(Russian)Bahrain(Arabic) Iraq(Arabic) Egypt(English) Ghana(English) Israel(English) Kuwait(English) Morocco(Arabic) Oman(Arabic) Qatar(Arabic) Saudi Arabia(Arabic) South Africa(English) Tanzania(English) Turkey(English) UAE(Arabic) Uganda(English) Algeria(Arabic) Nigeria(English) Ethiopia(English) Congo(French) Iran(English) Tanzania(English) Kenya(English) Sudan(Arabic)

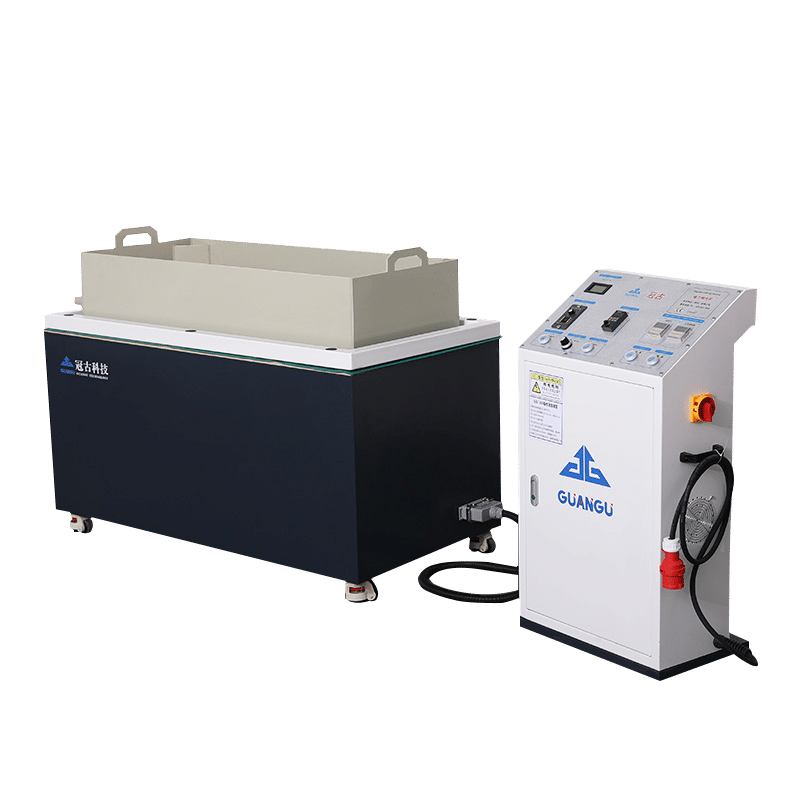

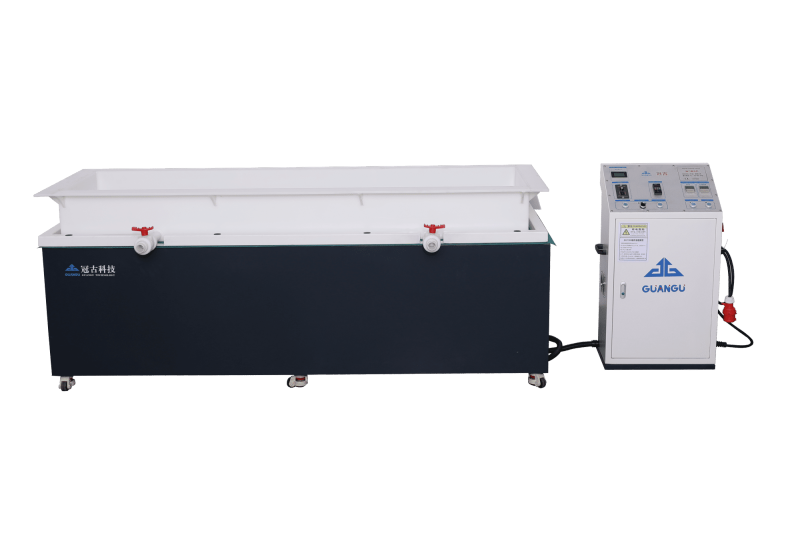

GG8520

GG8520 GG8620

GG8620 GG8720

GG8720 GG1380

GG1380 GG2380

GG2380 GG2980

GG2980 GG8850

GG8850 GG1980

GG1980 flipping

flipping flameproof

flameproof sandblaster

sandblaster Flat polishing machine

Flat polishing machine