With the rapid development of China's manufacturing industry, the Grinding process of precision parts is increasingly concerned. Magnetic Polishing Machine as a new type of grinding equipment, with its high efficiency, environmental protection, automation features, stand out in the field of grinding. Especially the automatic separation of grinding steel needle technology, but also become the industry's new favorite, for the development of China's manufacturing industry to inject new momentum.

First, the magnetic polishing machine overview

Magnetic polishing machine is a kind of equipment that utilizes magnetic grinding media to grind the workpiece, with the following advantages:

1. high efficiency: magnetic polishing machine using high-speed rotation of the magnetic field, so that the grinding media on the workpiece for all-round, dead-end grinding, greatly improving the grinding efficiency.

2. high precision: magnetic polishing machine can adjust the magnetic field strength according to the shape and size of the workpiece, to achieve precision grinding of the workpiece.

3. environmental protection: magnetic polishing machine adopts water-based grinding liquid, no pollution, in line with China's environmental policy.

4. High degree of automation: magnetic polishing machine can realize automatic operation, reduce labor cost and improve production efficiency.

Second, automatic separation of grinding steel needle technology

Automatic separation of grinding steel needle technology is the core component of the magnetic polishing machine, its main principles are as follows:

1. Grinding steel needles: the grinding steel needles made of special material are characterized by high hardness and strong wear resistance.

2. automatic separation: in the grinding process, the steel needle is automatically separated from the workpiece, grinding liquid and other impurities to avoid secondary pollution.

3. Recycling: the separated steel needles can be recycled to reduce the production cost.

Third, the Application of magnetic polishing machine in the industry

1. Precision parts manufacturing: magnetic polishing machine is widely used in aerospace, automotive, electronics, medical equipment and other industries for precision parts grinding.

2. surface treatment: magnetic polishing machine can be used for workpiece surface deburring, de-oxidized skin, polishing and other treatments to improve the surface quality of the workpiece.

3. mold industry: magnetic polishing machine can be used for mold grinding, polishing, improve mold precision and service life.

Fourth, magnetic polishingmachine market outlook

1. market demand: with the rapid development of China's manufacturing industry, the growing demand for precision parts grinding process, magnetic polishing machine market prospects.

2. Policy support: our government attaches great importance to the development of manufacturing industry, encouraging enterprises to adopt advanced technology to improve product quality, magnetic polishing machine as a new grinding technology, will be strongly supported by the policy.

3. Alternative to traditional grinding equipment: magnetic polishing machine has many advantages, is expected to gradually replace the traditional grinding equipment, become the mainstream of the industry.

In short, the magnetic polishing machine automatically separates the grinding steel needle technology with its high efficiency, environmental protection, automation and other characteristics, has become the new favorite in the field of grinding. In the context of China's manufacturing industry continues to develop, magnetic polishing machine market prospects are promising, is expected to inject a new impetus for the development of China's manufacturing industry.

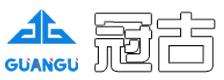

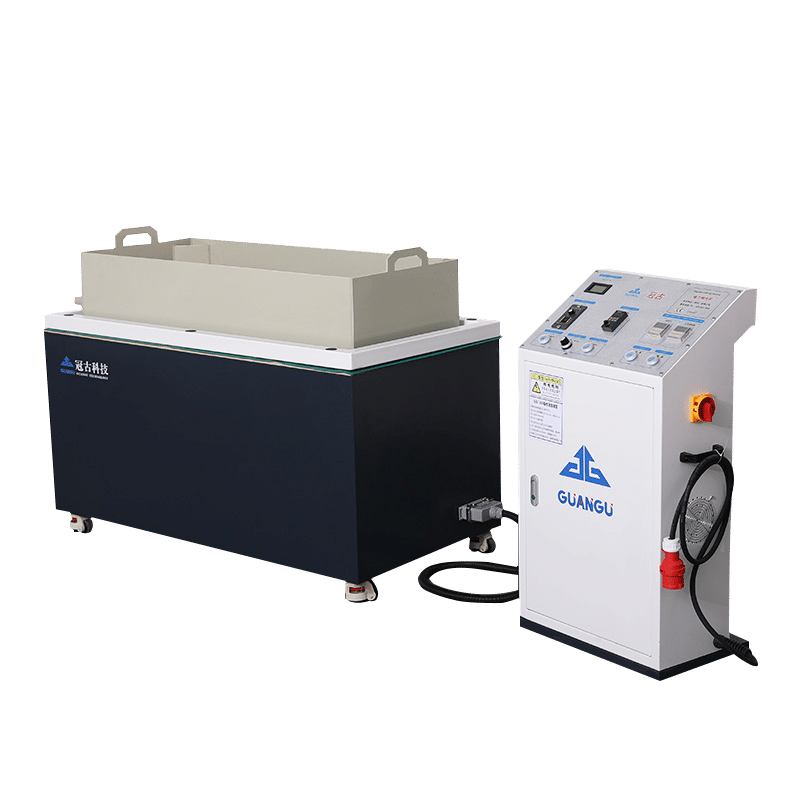

GG8520

GG8520 GG8620

GG8620 GG8720

GG8720 GG1380

GG1380 GG2380

GG2380 GG2980

GG2980 GG8850

GG8850 GG1980

GG1980 flipping

flipping flameproof

flameproof sandblaster

sandblaster Flat polishing machine

Flat polishing machine