In the precision manufacturing arena, the "last mile" of workpiece surface finishing often determines product quality and competitiveness. Whether it's gears and bearings in automotive parts, aluminum alloy casings in 3C electronics, or Stainless steel components in medical devices, deburring, polishing, and cleaning are like "industrial beauticians," directly affecting the product's sealing, corrosion resistance, assembly precision, and even appearance. However, the efficiency bottlenecks, human error, and cost pressures of traditional decentralized processing models remain a persistent pain point for manufacturing companies.

When "Three Processes" Meet "One Machine"—Guangu Technology Breaks Through with Innovation

As a national high-tech enterprise specializing in intelligent manufacturing equipment, Guangu Technology has been deeply involved in the surface treatment field for over a decade. Addressing industry pain points, it has launched an integrated deburring, polishing, and cleaning machine. With "integration, intelligence, and high efficiency" as its core, it integrates deburring, polishing, and cleaning processes onto a single platform, completely rewriting the traditional logic of precision manufacturing post-processing.

I. The Dilemma of Traditional Processes: The "Efficiency Trap" of Decentralized Processing

Before the advent of integrated processing machines, the post-processing workflow for most companies was as follows:

• Deburring: Relying on manual hand-held files, belt sanders, or single deburring machines, requiring multiple clamping operations, accounting for over 40% of the time;

• Polishing: Transferring to a polishing machine, changing fixtures, adjusting parameters, the surface roughness compliance rate depends on worker experience;

• Cleaning: Then sending to a cleaning line for degreasing, dewaxing, and rust prevention, resulting in high wastewater treatment costs and a significant risk of cross-contamination.

This segmented operation model presents three major challenges for enterprises:

1. Efficiency Loss: Three clamping operations plus two transfers increase single-piece processing time by 30%-50%, exacerbating delivery pressure;

2. Quality Fluctuations: Poor consistency in manual operation leads to frequent problems such as burr residue, uneven polishing, and incomplete cleaning, resulting in a defect rate as high as 5%-8%;

3. High Costs: Multiple machines occupy a large area, requiring a large workforce (3-5 people/line), and energy and maintenance costs are compounded.

Manufacturing enterprises urgently need a "one-stop" solution to transform post-processing from a "bottleneck" into an "efficiency engine."

II. Guangu Integrated Machine: Reconstructing Production Logic Through Technological Integration

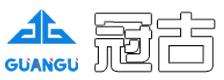

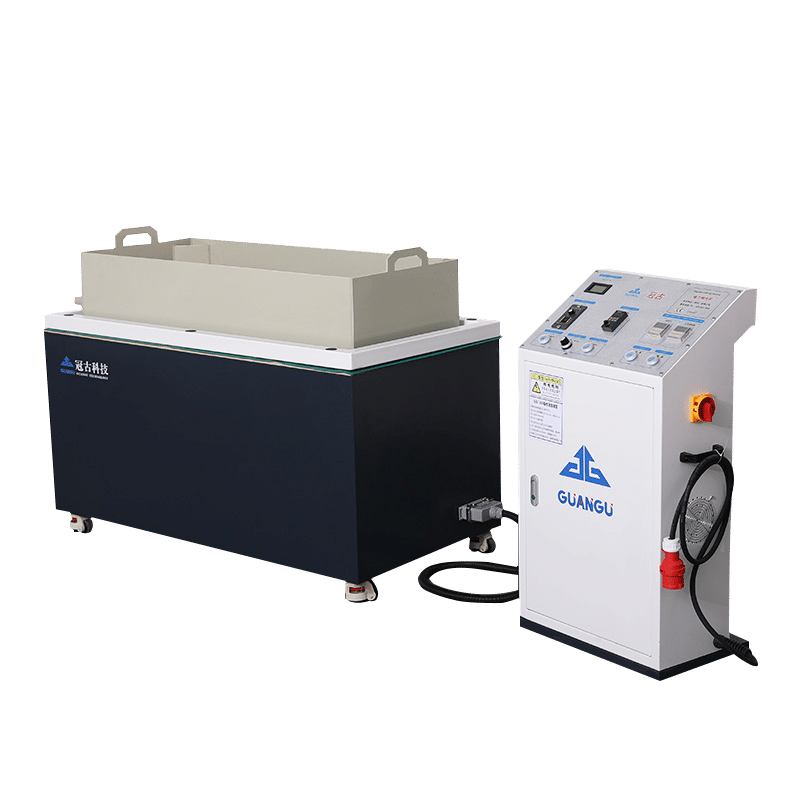

The core breakthrough of Guangu's deburring, polishing, and cleaning integrated machine lies in the deep synergy of "process integration" and "intelligent control." Through modular design and CNC system linkage, the equipment achieves full automation from burr removal to final cleaning, making "1+1+1>3" a reality.

1. Integrated Design, Space-Saving and Convenient

The equipment adopts a compact frame structure, integrating the deburring module (floating spindle + customized cutters), polishing module (centrifugal Grinding head/nylon wheel), and cleaning module (high-pressure spray + circulating filtration) into a single frame. Workpieces only need to be clamped once and automatically transferred to each process via a rotating worktable or robotic arm, eliminating cross-equipment transfers and multiple positioning errors. Space occupancy is reduced by 60% compared to traditional production lines, and manual inspection frequency is reduced by 70%.

2. Intelligent Multi-Process Collaboration, Dual Improvement in Precision and Efficiency

• Deburring: Flexible Force Control, No Damage to the Workpiece

Equipped with a force feedback floating spindle, the cutting force is automatically adjusted according to the workpiece material (stainless steel, aluminum alloy, Copper, etc.) and burr hardness. Combined with 3D vision positioning, it accurately removes tiny burrs from complex structures such as internal holes, intersecting holes, and curved surfaces (minimum burr size of 0.05mm), avoiding dimensional deviations caused by overcutting. • Polishing: Adjustable parameters, high consistency

The polishing module supports multi-dimensional programming of speed (500-8000rpm), pressure (0.1-2N), and time (0-300s). Combined with different abrasive combinations (ceramic abrasive, diamond paste), it can quickly switch between mirror polishing (Ra≤0.2μm), matte polishing, and other processes, with a stable yield rate of over 99.5%.

• Cleaning: Environmentally friendly and efficient, residue-free

The cleaning section uses a combination of "high-pressure spray + ultrasonic assistance + circulating filtration," allowing for customized cleaning programs for contaminants such as cutting fluid, oil, and wax. Combined with hot air drying, it ensures no liquid residue on the workpiece surface, achieving an 85% reuse rate of cleaning water and reducing wastewater treatment costs.

3. Full-process digitalization, enabling traceable and easily optimized production

The equipment has a built-in industrial internet system that supports real-time monitoring of parameters for each process (such as spindle load, polishing temperature, and cleaning water pressure). Abnormal data automatically triggers alarms and pushes them to the management terminal. Meanwhile, processing data (time, process parameters, quality inspection results) for each batch of workpieces can be stored in the cloud, facilitating quality review and process optimization. For mass production enterprises, it can also be integrated with the MES system to achieve intelligent scheduling of post-processing stages.

III. From "Usable" to "Effective": The Adaptability of the GuanGu All-in-One Machine

Currently, this equipment is widely used in automotive parts (gearbox housings, motor end covers), 3C electronics (phone frames, heat sinks), medical devices (surgical instruments, orthopedic implants), and aerospace (titanium alloy structural components), with significant advantages in the following scenarios:

• Small batch, multi-variety production: Meets customized production needs through rapid mold changeover (fixture switching time < 10 min) and parameter calling;

• High-precision workpieces: For example, aerospace aluminum alloy blades (tolerance ±0.02mm), the equipment avoids processing deformation through force control and visual compensation;

• Cleanroom requirements: Fully enclosed protection + negative pressure dust removal design, dust and liquid leakage < 0.1mg/m³, meeting GMP, ISO 14644 and other cleanroom standards.

Data from a car parts company's actual testing shows that after introducing the GuanGu integrated machine, the number of personnel on the after-processing line was reduced from 5 to 2, the single-piece processing time was shortened from 45 minutes to 18 minutes, the defect rate dropped from 6% to 0.8%, and the annual comprehensive cost was reduced by over 800,000 yuan.

IV. Choosing GuanGu: More Than Just a Machine, It's a Long-Term Competitive Advantage

In the wave of intelligent manufacturing, the value of equipment has extended from "single-machine performance" to "ecosystem collaboration." GuanGu Technology not only provides cost-effective integrated machines, but also offers:

• Customized Services: Providing full-cycle support such as fixture design and program debugging based on workpiece drawings and process requirements;

• Lifetime Technical Support: A nationwide 24-hour after-sales team, combining remote diagnostics and on-site service to ensure an OEE (Overall Efficiency) of ≥90%;

• Process Knowledge Base: A database of processing parameters for over 1000 workpieces, allowing new customers to quickly import mature solutions and shorten the debugging cycle.

Conclusion From "three processes" to "one machine does it all," Guangu Technology's deburring, polishing, and cleaning integrated machine represents not just an equipment upgrade, but a revolution in precision manufacturing post-processing. When efficiency, precision, and cost are no longer contradictory, companies can invest more resources in core R&D and leap towards high-end manufacturing.

If you are looking for a "smarter, more worry-free, and more profitable" post-processing solution, consider talking to Guangu Technology—let us use one machine to bridge the "last mile" of precision manufacturing for you.

GG8520

GG8520 GG8620

GG8620 GG8720

GG8720 GG1380

GG1380 GG2380

GG2380 GG2980

GG2980 GG8850

GG8850 GG1980

GG1980 flipping

flipping flameproof

flameproof sandblaster

sandblaster Flat polishing machine

Flat polishing machine