With the rapid development of my country's economy, people's living standards are constantly improving, and the pursuit of quality of life is getting higher and higher. As an important equipment for improving water quality, water purifiers have gradually become a necessary household appliance. In the production process of water purifiers, the processing quality of metal parts directly affects the performance and service life of the equipment. This article will introduce the Application of Magnetic Polishing Machine in the processing of metal parts of water purifiers.

1. Principle and characteristics of magnetic polishing machine

Magnetic polishing machine is a device that uses magnetic field to polish metal parts. It mainly grinds the surface of parts by magnetic abrasives to achieve the purpose of removing burrs, oxide scales and improving finish. Magnetic polishing machine has the following characteristics:

High polishing efficiency: Magnetic polishing machine uses magnetic abrasives, fast Grinding speed and short processing cycle.

Good polishing quality: Magnetic polishing machine can achieve mirror effect and effectively improve the surface finish of parts.

Strong adaptability: Magnetic polishing machine can process metal parts of various shapes and sizes, with a wide range of applications.

Easy operation: The magnetic polishing machine has a high degree of automation, is easy to operate, and saves labor costs.

Safe and environmentally friendly: The magnetic polishing machine uses water-soluble abrasives, is pollution-free, and meets environmental protection requirements.

2. Application of magnetic polishing machine in the processing of metal parts of water purifiers

Polishing of water purifier shell

As the appearance part of the product, the surface quality of the water purifier shell is crucial. The magnetic polishing machine can efficiently polish the shell, remove defects such as oxide scale and burrs, improve the surface finish, and make the shell more beautiful.

Polishing of internal parts of water purifiers

The processing quality of internal parts of water purifiers such as filter elements, valves, joints, etc. directly affects the filtering effect and service life of the equipment. The magnetic polishing machine can finely polish these parts, remove burrs and oxide scales, improve the surface finish, and ensure that the parts have good sealing performance after assembly.

Polishing of Stainless steel parts of water purifiers

Stainless steel parts are widely used in water purifiers, such as flanges and nuts. The magnetic polishing machine can efficiently polish stainless steel parts, remove oxide scales and burrs, improve the surface finish, prevent parts from corrosion, and extend service life.

Polishing of special-shaped parts of water purifiers

The magnetic polishing machine has strong adaptability and can polish special-shaped parts of water purifiers, such as elbows, tees, etc. Through magnetic polishing, the surface quality of special-shaped parts can be improved to ensure the normal operation of the equipment.

III. Conclusion

In short, the magnetic polishing machine has a wide range of application prospects in the processing of metal parts of water purifiers. Using a magnetic polishing machine for metal parts processing can not only improve production efficiency and reduce costs, but also ensure product quality and meet consumers' demand for high-quality life. With the continuous advancement of magnetic polishing technology, it is believed that its application in the water purifier industry will be more extensive.

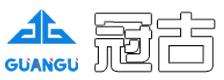

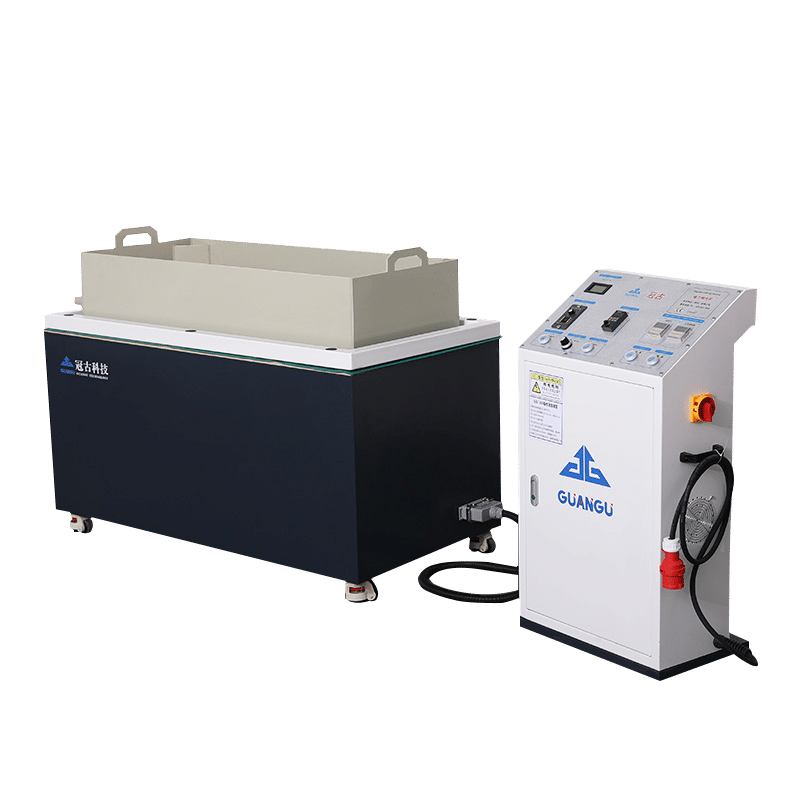

GG8520

GG8520 GG8620

GG8620 GG8720

GG8720 GG1380

GG1380 GG2380

GG2380 GG2980

GG2980 GG8850

GG8850 GG1980

GG1980 flipping

flipping flameproof

flameproof sandblaster

sandblaster Flat polishing machine

Flat polishing machine