With the rapid development of my country's manufacturing industry, five-axis CNC parts processing technology has become increasingly mature, providing a strong guarantee for the processing of high-precision and complex parts. This article will introduce the advantages of five-axis CNC parts processing and the important role of Magnetic Polishing Machines in improving the quality of parts processing.

1. Advantages of five-axis CNC parts processing

High precision and high efficiency

The five-axis CNC machine tool has five coordinate axes, which can realize all-round processing of workpieces. Compared with traditional three-axis CNC machine tools, five-axis machine tools have significant advantages in processing complex curved surfaces and special-shaped parts. At the same time, five-axis processing can complete multiple processes at one time, greatly improving production efficiency.

Strong adaptability

Five-axis CNC machine tools are suitable for processing various materials (such as metals, plastics, ceramics, etc.), and are widely used in aerospace, automobiles, molds, medical equipment and other fields. Its strong adaptability provides strong support for the development of my country's manufacturing industry.

Cost saving

Five-axis CNC processing can reduce the number of workpiece clamping times, reduce labor costs and equipment losses. At the same time, high-precision processing improves the utilization rate of raw materials and further reduces production costs.

Good stability

The five-axis CNC machine tool adopts advanced control systems and precise transmission devices to ensure the stability of the processing process. During high-speed and high-precision processing, the surface quality of the workpiece is effectively guaranteed.

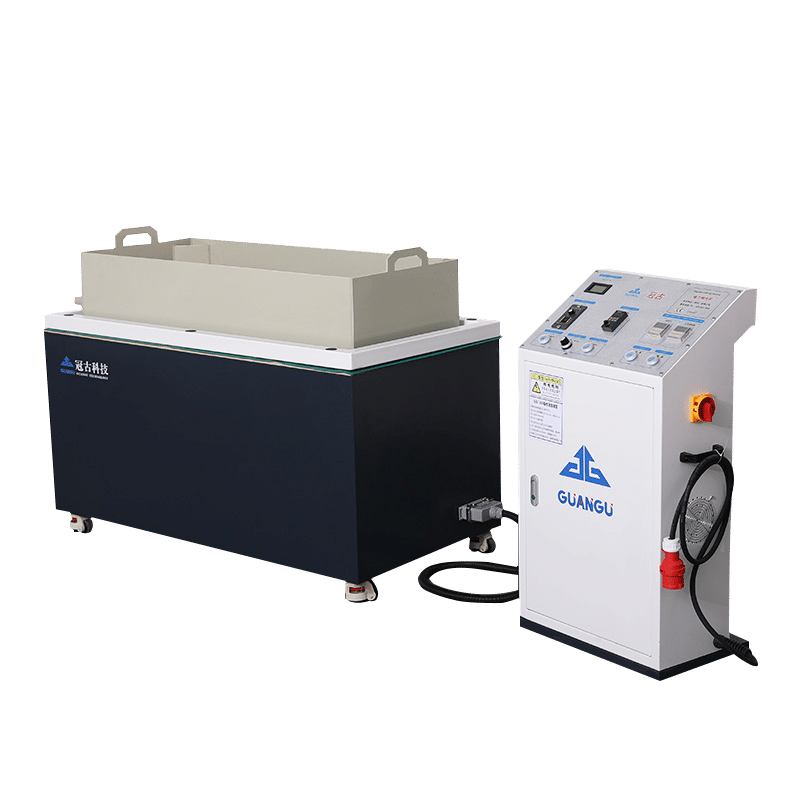

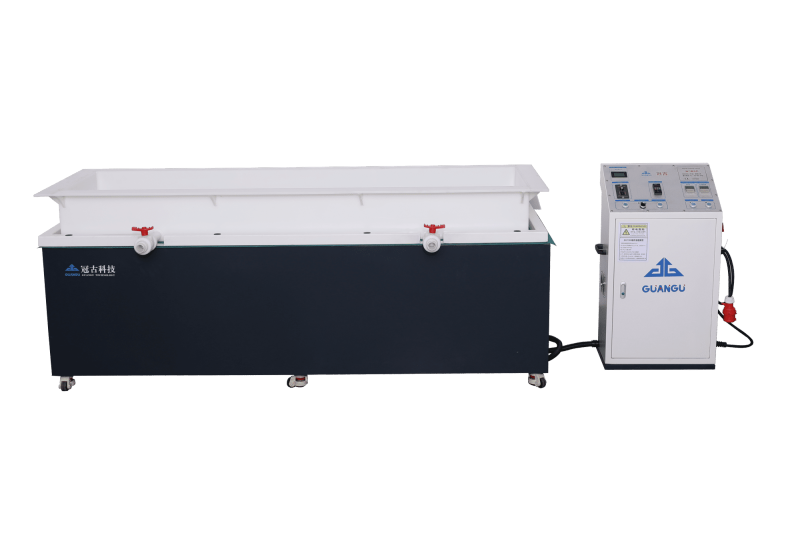

2. Application of magnetic polishing machine in five-axis CNC parts processing

The principle of magnetic polishing machine

The magnetic polishing machine uses the effect of the magnetic field to make the polishing medium (Grinding steel needle) roll on the workpiece at high speed, thereby achieving the purpose of removing burrs and polishing the surface. Compared with traditional polishing methods, magnetic polishing has the following advantages:

(1) Fast polishing speed and high efficiency;

(2) Uniform polishing without dead angles;

(3) Strong adaptability to the shape and size of the workpiece;

(4) Easy to operate, safe and environmentally friendly.

Application of magnetic polishing machine in five-axis CNC parts processing

(1) Improve the surface quality of parts

Although the five-axis CNC processing process has a high precision, there may still be tiny burrs on the surface of the parts. Through the treatment of the magnetic polishing machine, these burrs can be removed and the surface quality of the parts can be improved.

(2) Reduce the difficulty of subsequent processing

The parts processed by the magnetic polishing machine have a smooth and flat surface, which is conducive to the subsequent coating, electroplating and other processes. At the same time, the grinding and polishing processes in the subsequent processing are reduced, reducing the production cost.

(3) Extend the service life of the workpiece

The parts polished by the magnetic polishing machine have reduced surface roughness, improved wear resistance and corrosion resistance, thereby extending the service life of the workpiece.

In short, the five-axis CNC parts processing technology has provided a strong impetus for the development of my country's manufacturing industry. The magnetic polishing machine plays an important role in improving the quality of parts processing and reducing production costs. With the continuous optimization and popularization of these two technologies, it is believed that my country's manufacturing industry will move to a higher level.

GG8520

GG8520 GG8620

GG8620 GG8720

GG8720 GG1380

GG1380 GG2380

GG2380 GG2980

GG2980 GG8850

GG8850 GG1980

GG1980 flipping

flipping flameproof

flameproof sandblaster

sandblaster Flat polishing machine

Flat polishing machine