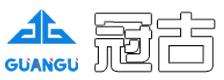

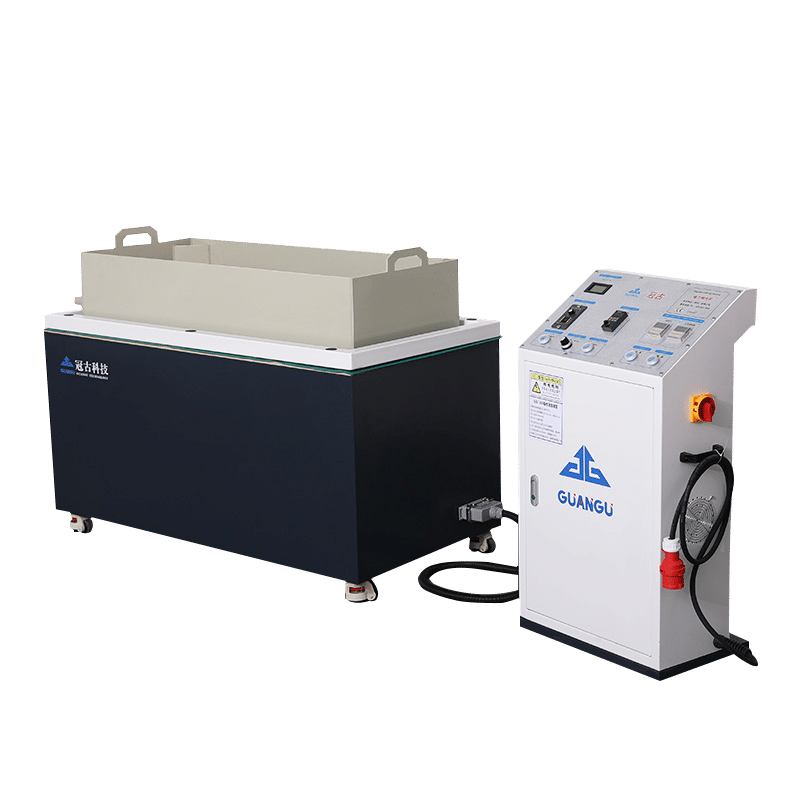

Magnetic deburring machine gg8620

Magnetic polishing machine

Model: GG8620

Brand: Guangu

Product Name: Magnetic Polishing Machine

Power supply: AC380V(50\60HZ)16A

Equipment size: 740*700*1088

Grinding tank size: 450*450

Motor power: 3.0KW*1

Machine weight: 188KG

Operation mode: forward and reverse

Maximum processing capacity: 10-12KG

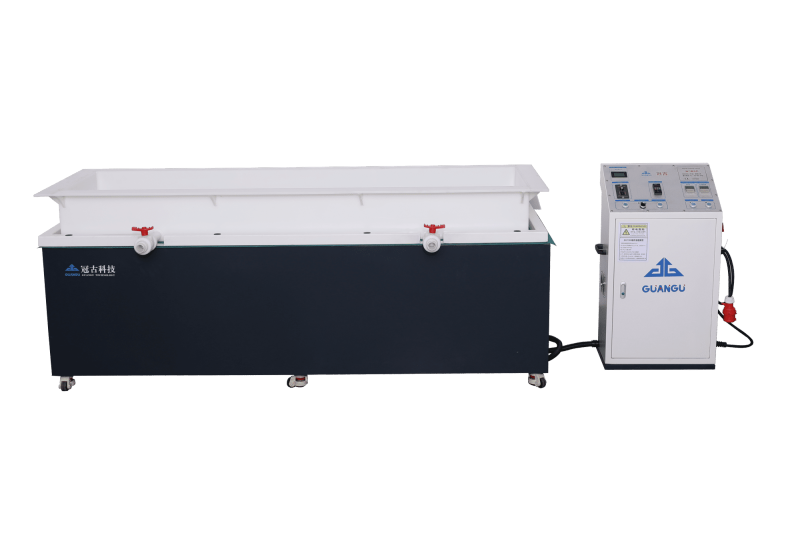

Development trend of magnetic grinding machine for copper parts

With the development of society, this makes our demand for many things is becoming higher and higher, and this polishing is also a. In the past, artificial polishing can not adapt to the social needs of today, so the development of society is also the need for us to have copper magnetic grinding machine.

Copper magnetic grinding machine is the use of magic magnetic field jumping force conduction to stainless steel needle, grinding needle, grinding material; Produce entrain workpiece high frequency rotating flow, vibration, reverse tumbling, across the workpiece surface, early workpiece inner hole, internal and external teeth and surface, concave and convex surface friction, to achieve cleaning, oil dirt impurities, burr removal, grinding and other precision polishing effect.

Most customers in the purchase of copper magnetic grinding machine, grinding in the choice of magnetic needle is not very easy to make a decision.

The choice of magnetic needle is mainly based on the quality standard of your product appearance. The coarser the steel needle, the shorter the grinding time will be, but the surface will be thicker. On the contrary, the fine grinding time of the steel needle will be longer. If your workpiece is more dead Angle, the fine steel needle will be grinding to get some bit. Relatively speaking, the surface of the grinding out will be smooth, feel better.

Magnetic grinding machine for copper plate copper bar cleaning to remove oxidation layer

Copper sheet copper bar is often used in the construction of electrical circuit connection engineering, it belongs to a kind of copper parts. There are many manufacturers of copper parts. Circuit and electrical connection engineering construction manufacturers often consider the smooth surface of copper bar when choosing copper plate copper bar. Therefore, after the processing of copper sheet copper bar is completed, its surface often needs to be cleaned to remove the oxide layer.

Copper sheet polished to remove oxidation layer

Copper sheet is often used in the production of conductive modules, which belongs to a kind of copper parts. There are many manufacturers of copper parts. Conductive and thermal module manufacturers often consider whether the surface of the workpiece is reflective, smooth and beautiful when choosing copper pieces. Therefore, after the processing of copper sheet, its surface often needs to be polished to remove the oxide layer.

GG8520

GG8520 GG8620

GG8620 GG8720

GG8720 GG1380

GG1380 GG2380

GG2380 GG2980

GG2980 GG8850

GG8850 GG1980

GG1980 flipping

flipping flameproof

flameproof sandblaster

sandblaster Flat polishing machine

Flat polishing machine