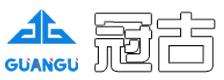

Magnetic polishing machine gg8520

Magnetic polishing machine/magnetic deburring polishing machine

Model: GG8520

Brand: Guangu

Product name: small magnetic polishing machine

Power supply: AC380V(50\60HZ)16A

Equipment size: 640*600*1080

Grinding tank size: 350mm

Motor power: 2.2KW*1

Machine weight: 168kg

Operation mode: forward and reverse

Maximum processing capacity: 8-10KG

Deoxidizing magnetic polishing machine description:

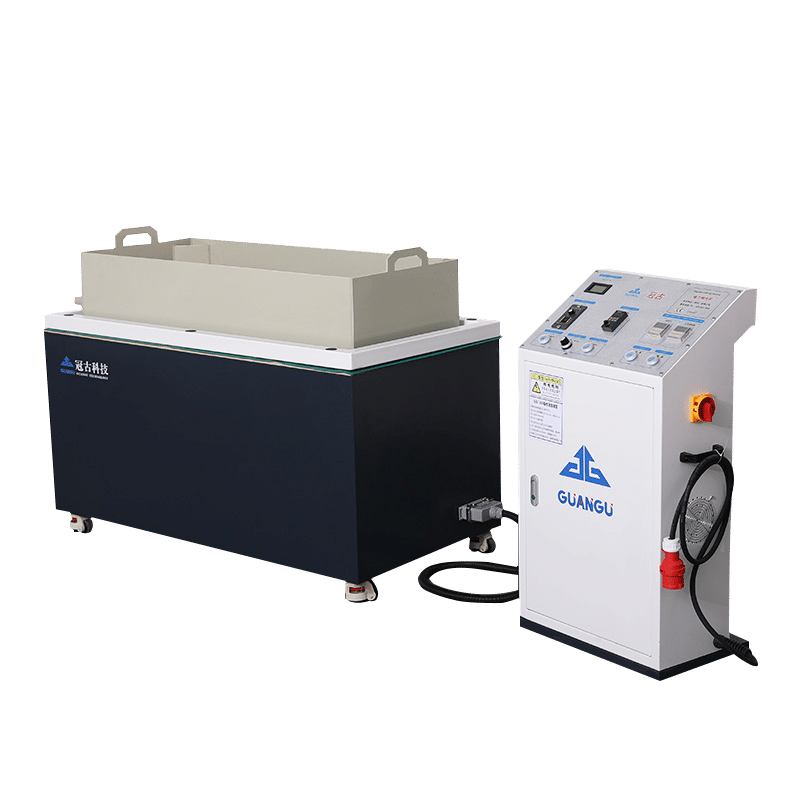

1. Magnetic grinding speed is fast, the average grinding time is about 5 minutes to 15 minutes, equipped with double processing groove to replace the workpiece quickly, can replace the grinding parts in the operation of the equipment;

2. Simple operation, one person can operate several machines;

4. No pollution, the grinding liquid contains 97% water, so there is no toxicity and fire risk, fully in line with environmental protection discharge standards;

5 magnetic grinding after completion, the workpiece is good treatment, available screen, needle separator or vibrating screen can easily separate the workpiece and stainless steel needle;

6 stainless steel needle diameter 0.2*3MM to 2.0*10MM for choice;

Deoxidizing magnetic polishing custom time, fast processing speed, simple operation and safe variable frequency adjustment, meet various polishing needs polishing deburring no dead Angle end reminder, can remind polishing completion, can be operated by a person multiple sets of voltage, current, frequency, time can be set, simple and clear polishing process without manual intervention (can be customized according to customer requirements specifications, capacity).

Magnetic grinding machine for copper plate copper bar cleaning to remove oxidation layer

Copper sheet copper bar is often used in the construction of electrical circuit connection engineering, it belongs to a kind of copper parts. There are many manufacturers of copper parts. Circuit and electrical connection engineering construction manufacturers often consider the smooth surface of copper bar when choosing copper plate copper bar. Therefore, after the processing of copper sheet copper bar is completed, its surface often needs to be cleaned to remove the oxide layer.

Copper sheet polished to remove oxidation layer

Copper sheet is often used in the production of conductive modules, which belongs to a kind of copper parts. There are many manufacturers of copper parts. Conductive and thermal module manufacturers often consider whether the surface of the workpiece is reflective, smooth and beautiful when choosing copper pieces. Therefore, after the processing of copper sheet, its surface often needs to be polished to remove the oxide layer.

GG8520

GG8520 GG8620

GG8620 GG8720

GG8720 GG1380

GG1380 GG2380

GG2380 GG2980

GG2980 GG8850

GG8850 GG1980

GG1980 flipping

flipping flameproof

flameproof sandblaster

sandblaster Flat polishing machine

Flat polishing machine