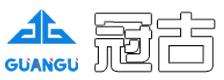

Translating Magnetic Polishing Machine GG8850

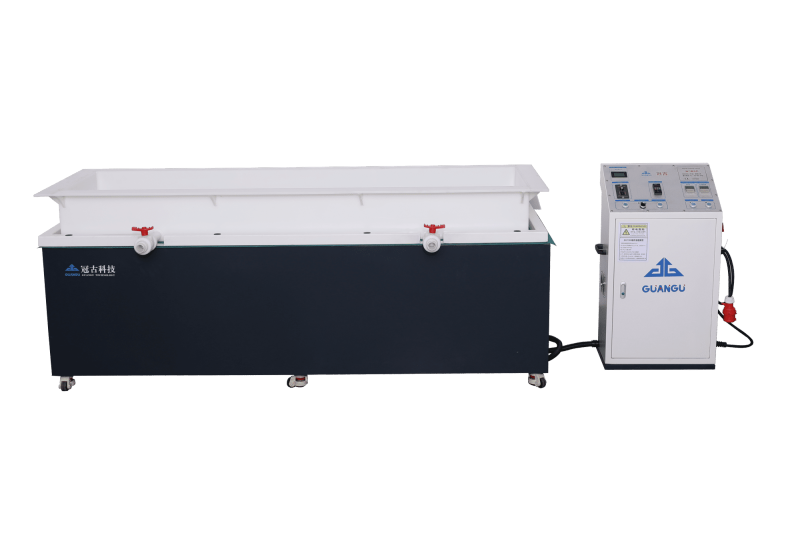

Translation magnetic polishing machine

Model: GG8850

Brand: Guangu

Product Name: Magnetic Polishing Machine

Power supply: AC380V(50\60HZ)16A

Equipment size:1200*800*1088

Grinding tank size:900*500

Motor power: 4.0KW*1

Machine weight: 288KG

Operation mode: forward and reverse

Maximum processing capacity: 0-25KG

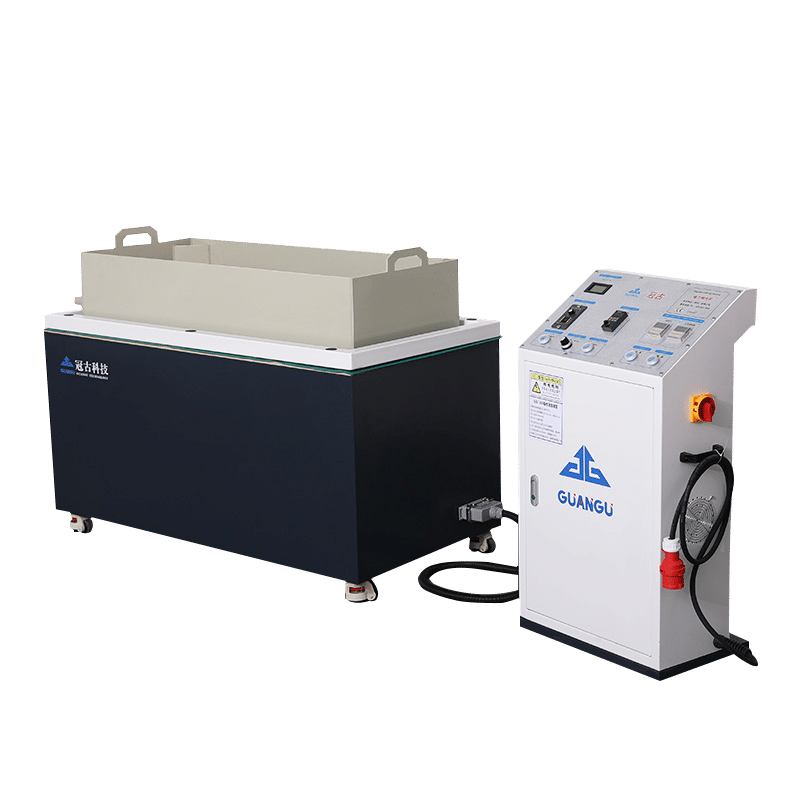

Gugugu magnetic vibration polishing machine is to use the power of the magnetic field to guide the grinding material (magnetic grinding needle) to rotate rapidly and grind the workpiece, to achieve efficient removal of raw edge (batching front), surface polishing, polishing, cleaning, oxidation film, sintering marks, rust and other grinding and cleaning effects. Workpiece surface polishing polishing polishing polishing, burring fly edge, batch front, to oxide film, to sintering mark, restore metal color cleaning, metal processing scraps, residue, batch front, surface plating, welding spot, metal surface paint removal, precision small shaped parts, irregular parts: removal of burr (burring, batch front), polishing, cleaning, chamfering, enhance surface hardness grinding at the same time; The minimum size of magnetic steel needle is 0.2mm*3mm, which can precision grind irregular parts such as holes, tubes, cracks, dead angles, right angles and screws of metal parts. Workpiece grinding process does not collide with each other, magnetic grinding after the product workpiece does not deformation, does not affect the accuracy, does not damage the surface.

Guan ancient magnetic vibration polishing machine operating points

1: Before magnetic polishing, it is necessary to clean the oil scale on the surface of the workpiece. The polishing liquid cannot remove a large amount of oil scale, otherwise the workpiece, polishing needle, water and polishing barrel may be black.

2: Cleaning liquid must be used when cleaning magnetic polishing needle and polishing barrel.

Guangru magnetic vibration polishing machine breaks through the traditional vibration polishing concept, using magnetic force to drag the stainless steel needle grinding material to produce rapid rotating motion, so as to achieve the removal of burr, polishing, cleaning and other multiple effects. Product summary of a large number of practical experience, through careful design, magnetic field distribution uniform, magnetic field drag power automatic smooth, reverse, polishing effect more uniform, object surface more smooth, product effect far beyond the domestic similar products! In addition, this product has a high cost performance, can completely replace similar imported products, is the first choice to save labor costs and improve work efficiency! This product adopts high quality magnet hinge drive and single chip microcomputer control, with perfect motor protection. Model specifications can be customized according to customer requirements.

Magnetic vibration polishing machine is suitable for the following industries: wood, furniture industry such as flat wood, furniture metal handle and other workpiece sanding drawing; Aluminum profiles and their products, stainless steel and utensils, copper profiles and their products, plumbing and sanitary ware, locks, lighting products, nameplates, hardware and crafts accessories, knives and scissors, door leaves, automobile and bicycle parts, tableware, condemnation products, buttons, belt buckles, mobile phone casings, watch and other workpieces sanding and drawing; Electronic parts, electronic equipment such as electronic parts, plate sanding drawing, etc.

GG8520

GG8520 GG8620

GG8620 GG8720

GG8720 GG1380

GG1380 GG2380

GG2380 GG2980

GG2980 GG8850

GG8850 GG1980

GG1980 flipping

flipping flameproof

flameproof sandblaster

sandblaster Flat polishing machine

Flat polishing machine