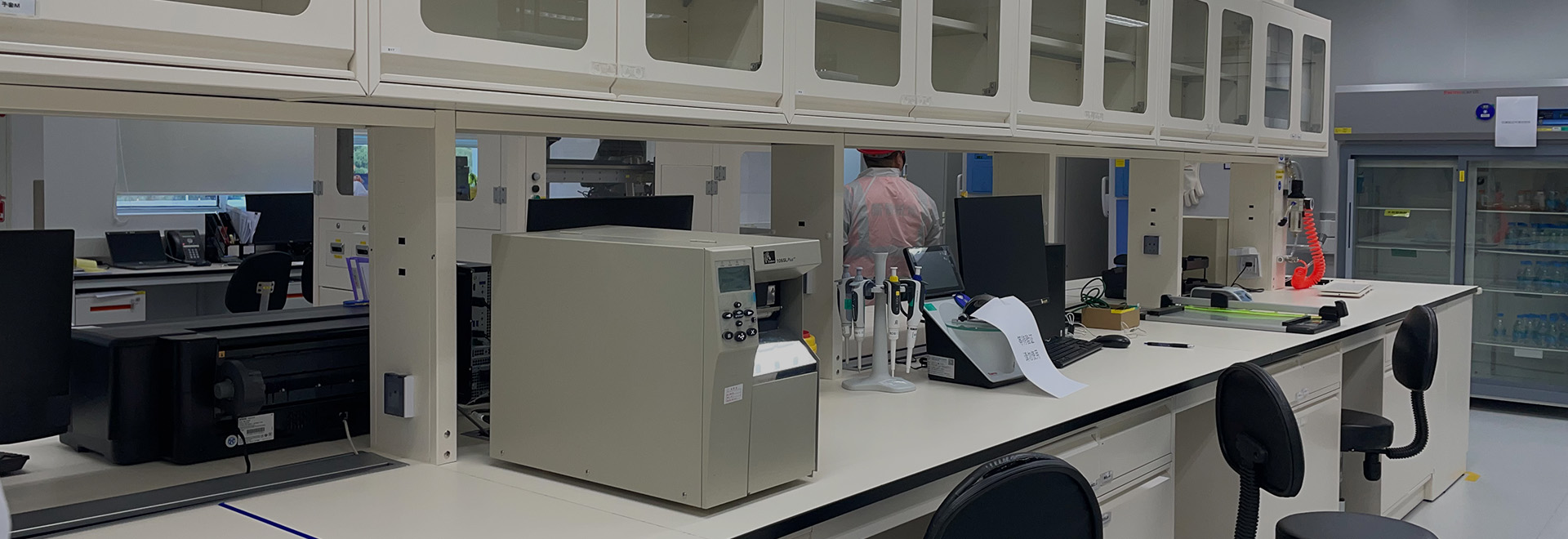

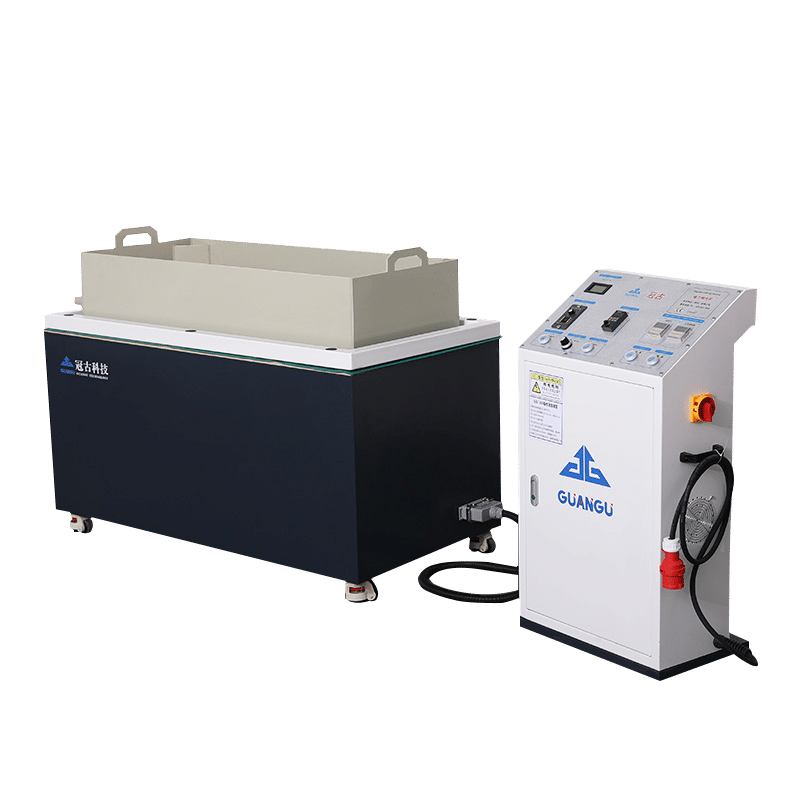

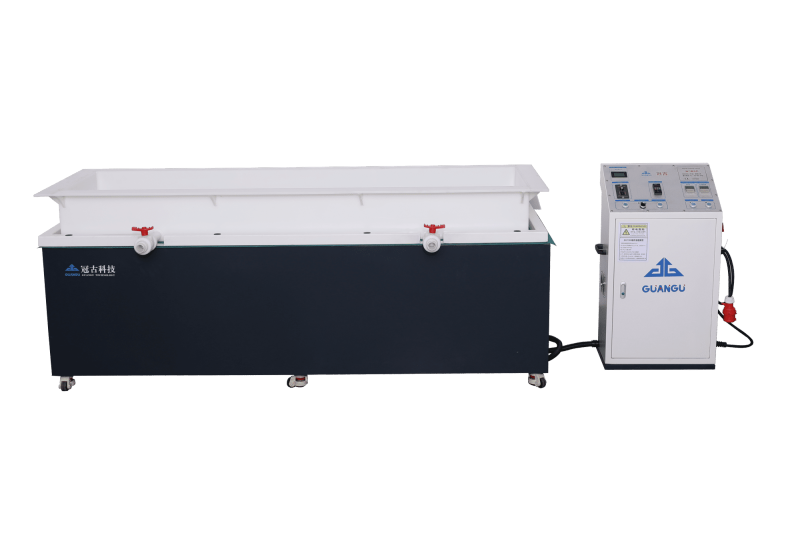

Translating Magnetic Polishing Machine gg1380

Translation magnetic tumbler

Model number: GG1380

Product name: translation magnetic polishing machine

Power supply: AC380V(50Hz)16A

Equipment size: 1380*720*1080

Grinding groove size: 1200*520

Motor power: 4.0KW*1

Machine weight: 410KG

Operation mode: positive and negative rotation and translation

Maximum processing capacity: 0-35KG

Stainless steel magnetic grinding machine is suitable for a wide range, when choosing the right type

Stainless steel magnetic grinders, while powerful, are not suitable for all factories. In different manufacturing industries, corresponding machines need to be configured. For the larger production requirements of the factory. To do a reasonable allocation of processing procedures. Make specific grinding arrangements according to each process.

The principles of the arrangement are as follows:

For regular objects, such as rotations, spheres, squares, plates, etc. You can easily have grinding anywhere. When choosing a model, you only need one of the same model. Can also be multiple processes, can also be parallel to form a line, so that can greatly improve the production efficiency.

For irregular objects. Such as special-shaped parts and so on. Need a variety of grinding specifications can choose different models, each model with different needle, advanced coarse polishing. Then enter the next process to select the fine needle for fine casting, so as to achieve fast + efficient + high quality production state.

What are the precautions for the use of Guan Gu stainless steel magnetic grinder

1: Do not splash liquid and water into the wire and plug of Guanguu stainless steel magnetic grinding machine.

2: The stainless steel magnetic grinding machine needs to be equipped with an overcurrent switch, it is recommended to choose a power supply above 6A.

3: After starting the power supply of the stainless steel magnetic grinding machine, pay attention to check whether the cold air cooling fan on the back cover is running normally.

4: stainless steel magnetic grinding machine do not work for a long time under low frequency, lightning may cause damage to the stainless steel magnetic grinding machine.

5: The use of stainless steel magnetic grinding machine must be grounded.

The key principle of stainless steel magnetic grinding machine is to try to get the polishing rate, so as to remove the damage layer produced when polishing as soon as possible. At the same time, the polishing damage layer should not affect the final observed tissue, that is, will not cause false tissue.

304 stainless steel connecting rod slip brace cleaning polishing deburring

304 stainless steel connecting rod slide brace is widely used in doors and Windows industry. Manufacturers of stainless steel slide brace hold the characteristics of waterproof and anticorrosive products, good wear resistance, strong friction ability and strong rust prevention ability based on the market. Polishing and deburring are very important in the process of stainless steel connecting rod sliding. The magnetic polishing machine is used to grind and polish the 304 stainless steel connecting rod slipper, which can make the surface of the stainless steel connecting rod slipper more metallic luster, and remove the excess burrs on the stainless steel connecting rod slipper.

Stainless steel precision parts cleaning and deburring

Stainless steel precision parts are often used in equipment assembly production, it belongs to a kind of precision parts. There are many manufacturers of precision parts. When selecting stainless steel precision parts, equipment assembly manufacturers often consider that the surface of the parts is clean and clean without burr. Therefore, after the completion of stainless steel precision parts processing, the surface often needs to be cleaned and deburring.

GG8520

GG8520 GG8620

GG8620 GG8720

GG8720 GG1380

GG1380 GG2380

GG2380 GG2980

GG2980 GG8850

GG8850 GG1980

GG1980 flipping

flipping flameproof

flameproof sandblaster

sandblaster Flat polishing machine

Flat polishing machine